The Future of Industrial Filtration Solutions: Technologies Driving Efficiency and Sustainability

Dec 3, 2025

Why Industrial Filtration Solutions Matter for Modern Manufacturing

Industrial filtration has become a mission-critical component of modern manufacturing, mining, chemical processing, wastewater treatment, and environmental protection. As factories scale up production and environmental regulations tighten worldwide, the ability to efficiently separate solids from liquids directly affects operational stability, cost control, and sustainability performance.

High-quality industrial filtration solutions ensure cleaner process fluids, reduced energy consumption, longer equipment lifespan, and improved waste management. From metal processing to pharmaceuticals and from food production to mineral extraction, filtration is essential for maintaining product quality and keeping facilities compliant with strict industry standards.

Across many sectors, upgrading filtration equipment—especially advanced systems such as the Hydraulic Filter Press—has become a strategic investment to boost productivity, lower maintenance costs, and achieve higher throughput.

Core Industrial Filtration Technologies Used Across Global Industries

Industrial filtration is not a one-size-fits-all process. Different industries require different levels of filtration efficiency, pressure capability, and automation. Below are the most widely adopted and effective filtration technologies used in industrial operations:

1. Filter Press Technology

Filter press solutions are the backbone of many industrial filtration processes. They provide exceptionally high solid–liquid separation efficiency and produce dry filter cakes suitable for disposal or resource recovery. Filter presses are commonly used in mining, metal finishing, ceramics, food production, and wastewater treatment.

Their ability to handle high solids concentration, corrosive materials, and demanding operating conditions makes them one of the most reliable choices for heavy-industry applications.

2. Automatic Filtration Systems

Many modern facilities operate continuously and require filtration systems that run with minimal downtime. This has led to the widespread adoption of automated filtration technologies such as PLC-controlled filter presses, automated plate shifters, self-cleaning strainers, and smart filter monitoring systems.

Automation enhances safety, reduces labor requirements, and ensures consistent filtration results—critical for high-capacity production lines. For example, many factories are transitioning to Automatic Filter Press Systems to achieve predictable cycle times and data-driven performance optimization.

3. Membrane Filtration

Membrane technology is essential for fine filtration, especially in food processing, pharmaceuticals, power generation, and high-purity applications. Membrane filtration includes microfiltration, ultrafiltration, nanofiltration, and reverse osmosis. Each delivers a specific range of particle separation based on pore size.

Membranes are ideal for tasks such as recycling process fluids, removing impurities, and filtering high-value materials without altering their chemical properties.

4. Centrifugal Separation

Centrifuges separate solids and liquids through rapid rotational force. These systems offer continuous operation and are ideal for sludge with variable viscosity or high-temperature materials. They excel in petrochemical processing, plastics manufacturing, and certain types of wastewater streams where rapid separation is required.

5. Industrial Cartridge and Bag Filters

These filtration systems are widely used for polishing filtration, protecting downstream equipment, and maintaining process fluid purity. Cartridge and bag filters are essential in chemical production, oil & gas processing, coatings manufacturing, and water purification.

How to Select the Right Industrial Filtration Equipment

Choosing the right filtration equipment requires evaluating multiple operational, environmental, and financial factors. For B2B buyers, this decision directly impacts production efficiency and long-term cost savings.

1. Understand Slurry Characteristics

The composition of the slurry—particle size, solids content, chemical properties, temperature, and abrasiveness—determines which filtration technology is most suitable.

For example, high-solids mineral slurries benefit from high-pressure filter presses, while fine chemical solutions may require membrane filtration.

2. Identify Required Filtration Efficiency

Industries needing extremely pure output, such as pharmaceuticals or electronics manufacturing, must use advanced membrane or cartridge systems.

Meanwhile, industries that prioritize moisture reduction and waste volume minimization may opt for heavy-duty filter presses.

3. Consider Operational Throughput

Some applications require continuous 24/7 operation, making automated and high-capacity filtration systems essential. Automatic filter presses or centrifuges are ideal for these demanding workflows.

4. Assess Energy Consumption and Operational Cost

Energy efficiency is becoming a key selection factor, especially for industries facing rising utility prices. Hydraulic presses and automated systems often provide significant energy savings over older mechanical equipment.

5. Plan for Integration, Maintenance, and Expansion

Filtration systems must integrate seamlessly with existing production lines. Buyers should also consider maintenance frequency, spare parts availability, and whether the equipment supports future capacity upgrades.

The Economic and Environmental Benefits of Modern Filtration Solutions

Upgrading to advanced industrial filtration solutions brings measurable improvements across several operational areas:

1. Lower Waste Disposal Costs

Efficient filtration reduces water content in industrial sludge, minimizing the volume requiring disposal and lowering transportation and landfill expenses.

2. Enhanced Resource Recovery

Many filtration processes enable companies to reclaim valuable materials—such as metals, pigments, chemicals, or reusable water—turning waste into profit.

3. Boosted Production Efficiency

Cleaner process fluids mean fewer equipment failures, longer service intervals, and more stable production cycles.

4. Reduced Environmental Risk

Modern filtration systems minimize emissions, wastewater discharge, and contamination incidents, helping factories meet national and international compliance standards.

5. Improved Worker Safety

Automation reduces manual handling, exposure to hazardous materials, and the risk of workplace accidents.

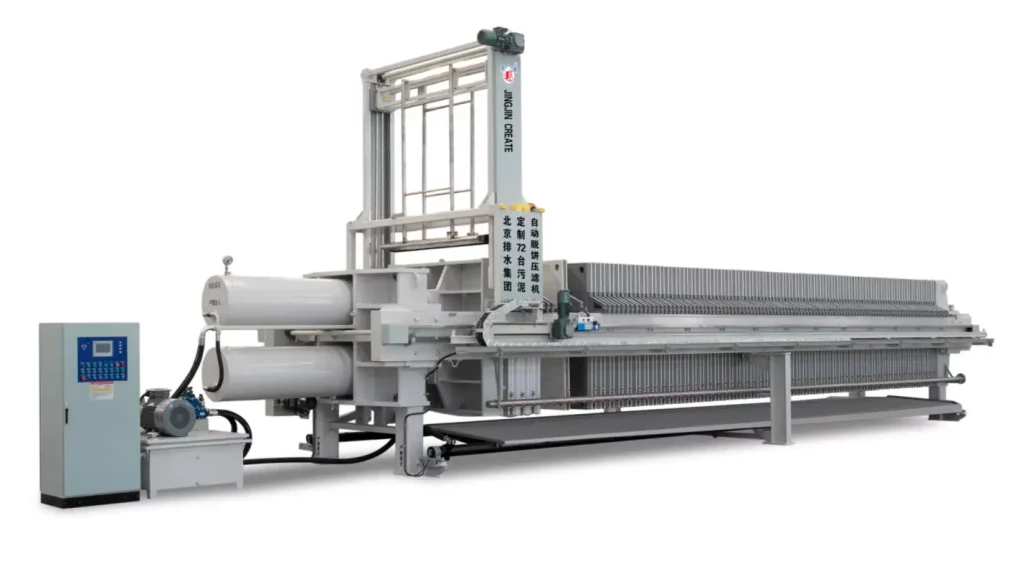

Why Jingjin Leads the Global Market in Industrial Filtration Solutions

As one of the world’s most trusted manufacturers of industrial filtration equipment, Jingjin delivers high-performance solutions engineered for demanding industrial environments. With decades of experience in filtration technology, the company provides a full portfolio of equipment including hydraulic filter presses, automatic filtration systems, membrane plates, chamber plates, filter cloths, and turnkey filtration lines.

Jingjin’s solutions are built for long-term durability, low energy consumption, and superior filtration efficiency. The company serves key industries such as mining, metallurgy, chemical processing, municipal wastewater, food manufacturing, and environmental engineering.

For global B2B customers seeking reliable, scalable, and cost-effective industrial filtration solutions, Jingjin offers engineering consultation, customized system design, on-site installation, and comprehensive after-sales support to ensure optimized performance from day one.