Solid Liquid Separation: How Can Industrial Facilities Optimize Filtration for Maximum Efficiency?

Fev 11, 2026

Solid liquid separation is a cornerstone process for industries ranging from chemical manufacturing to mining and wastewater treatment. Efficient separation of solids from liquids ensures product quality, protects downstream equipment, and reduces operational costs. The method chosen, whether filtration, centrifugation, or sedimentation, directly affects throughput, energy consumption, and system reliability.

Understanding how to implement effective solid liquid separation allows plant managers and engineers to optimize process performance, avoid downtime, and meet environmental compliance standards. In this article, we explore the techniques, technologies, and operational strategies that maximize separation efficiency in industrial applications.

Importance of Solid Liquid Separation in Industry

Solid liquid separation is vital for several reasons:

- Protects equipment from fouling, abrasion, and corrosion

- Improves product quality by removing impurities

- Reduces wastewater volume and environmental impact

- Enables recovery of valuable solids

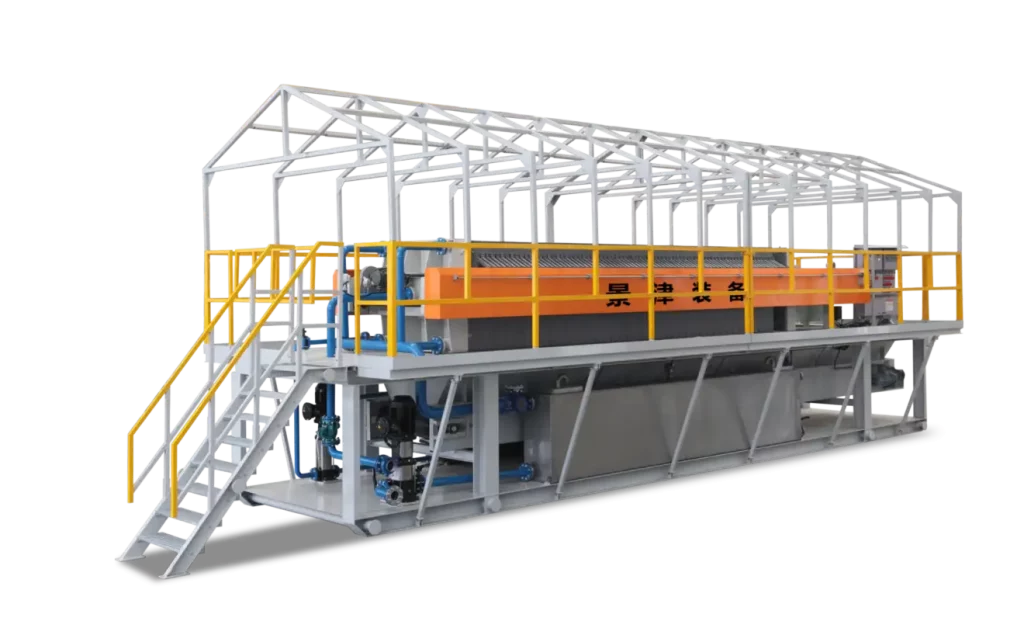

Industrial processes, such as mining and chemical manufacturing, rely heavily on industrial filter press systems to achieve high-efficiency separation with minimal downtime. Choosing the right technology ensures long-term operational stability.

Applications Across Industries

Mining: Separation of valuable minerals from slurry using filter presses prevents product loss and reduces water consumption.

Wastewater Treatment: Municipal and industrial facilities employ solid liquid separation to clarify effluent and comply with discharge regulations.

Chemical Manufacturing: High-viscosity slurries and fine particulate matter require precise separation methods to ensure consistency and safety.

Core Technologies for Solid Liquid Separation

Filtration

Filtration is one of the most widely used methods. It uses a porous medium to separate solids from liquids. Key parameters include filter medium type, pore size, and applied pressure.

- Filter Press: Offers high solid capture efficiency and is ideal for high-density slurries.

- Jig or Cartridge Filters: Suitable for smaller particles or lower throughput applications.

Centrifugation

Centrifugal force accelerates sedimentation of solids from liquids. Centrifuges are advantageous for high-speed processing but require higher energy input.

Sedimentation and Gravity Separation

Using natural settling allows heavy solids to precipitate under gravity. This method is energy-efficient but slower and may require large tanks.

Advanced Membrane Techniques

Membrane filtration, such as ultrafiltration and microfiltration, is increasingly applied in chemical and food industries for high-purity separation.

Optimizing Industrial Filter Press Performance

Selecting the Right Filter Press

Factors to consider include slurry properties, solids concentration, and required cake dryness. Choosing the correct Jingjin filter press model ensures consistent performance.

Operational Best Practices

- Maintain consistent feed pressure

- Monitor slurry viscosity

- Clean plates and cloths regularly

- Use automated systems to detect blockages

Maintenance and Monitoring

Routine inspections, integrity tests, and preventive maintenance schedules minimize downtime and extend plate life. Proper maintenance prevents leakage, uneven cake formation, and equipment wear.

If you want guidance on selecting and maintaining a filter press system, contact our experts for customized solutions.

Performance Metrics and Efficiency Analysis

Key Performance Indicators (KPIs)

- Cake dryness

- Filtrate clarity

- Cycle time

- Energy consumption

Monitoring these KPIs allows operators to optimize the separation process, reduce costs, and improve throughput.

Table 1: Typical Filter Press Performance Metrics

| Parameter | Typical Range | Measurement Method | Notes |

|---|---|---|---|

| Cake dryness | 45–65% | Gravimetric | Depends on slurry type |

| Filtrate clarity | <50 mg/L | Turbidity measurement | Affected by cloth selection |

| Cycle time | 30–120 min | Stopwatch/SCADA | Varies with feed concentration |

| Energy usage | 1–5 kWh/t | Power meters | Optimized with proper pressure and timing |

Troubleshooting Common Separation Issues

Uneven Cake Formation

- Cause: Misaligned plates or uneven slurry distribution

- Solution: Realign plates, ensure consistent feed

Filtrate Leakage

- Cause: Damaged filter cloth or gasket

- Solution: Replace damaged components and inspect sealing surfaces

Plate or Frame Wear

- Cause: High-abrasion slurries

- Solution: Use wear-resistant plates and implement preventive maintenance

Economic and Environmental Benefits

Effective solid liquid separation reduces operational costs, conserves water, minimizes chemical usage, and ensures compliance with discharge regulations. High-efficiency filtration contributes to sustainable operations and enhances profitability.

FAQ

What is solid liquid separation?

It is the process of separating solid particles from liquid in industrial applications using filtration, centrifugation, or sedimentation.

Why is it important in wastewater treatment?

It clarifies effluent, reduces pollutants, and ensures compliance with environmental standards.

How do filter presses improve separation?

Filter presses capture solids efficiently, produce high cake dryness, and allow automated operation for consistent performance.

How often should filter press maintenance be performed?

Daily visual inspection, weekly cleaning, and quarterly integrity checks are recommended.

Can membrane technologies replace traditional filter presses?

Membranes offer high-purity separation but may be cost-prohibitive for high-volume slurry applications.

About Jingjin

Jingjin specializes in industrial water and wastewater treatment and high-performance industrial filter press systems. As a leading provider of Jingjin filter press solutions, we serve mining, chemical, food, and municipal industries worldwide. Our expertise in solid liquid separation ensures high efficiency, reliability, and compliance for industrial operations.

References

- Solid-liquid separation – Wikipedia

https://en.wikipedia.org/wiki/Solid%E2%80%93liquid_separation - Filtration – U.S. Environmental Protection Agency

https://www.epa.gov/eg/industrial-water-quality - Industrial wastewater treatment fundamentals – Water Environment Federation

https://www.wef.org/resources/