Dynamic Simulation Analysis of Agitators Using Siemens CCM Software:

Jingjin analyzes the three – dimensional and cross – sectional flow fields in specific industries. This shows how materials flow inside reactors more clearly. As a result, we can quickly and accurately find the best solution. We can then choose the right stirring effect, power, speed, and stirring form.

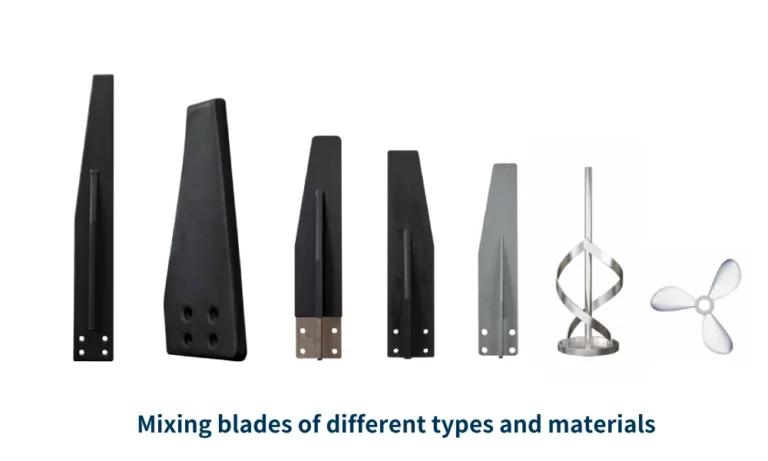

Classification of Agitator Stirring Paddles:

- For slurry, use three – blade or four – blade flat plates to stop materials from settling.

- Six – blade disc paddles mainly disperse and stir gases in solutions.

- Variable cross – section and variable inclination paddles mix, decompose, and make materials react.

- Use frame – type stirring paddles for high – viscosity materials to keep them from settling.

![]()

What are the advantages of Mixer Shaft?

- Efficient Mixing:The mixing blades on the mixing shaft can mix materials quickly. They ensure materials spread evenly and boost mixing efficiency.

- Stable Structure:People design the mixing shaft to be mechanically stable and durable. It can handle long – term use and heavy loads.

- Simple Maintenance:The mixing shaft has a straightforward design and is easy to take apart. This makes maintenance and cleaning jobs simple.

- High Adaptability:You can design and customize the mixing shaft for different industrial needs. It can meet various mixing requirements and handle different material properties.

- Less Wear:In twin – shaft mixers, during operation, concrete can build up between the two shafts. This reduces wear on the mixing arm and the bottom coating.

- Lower Failure Rate:A good design cuts down on the chances of breakdowns and makes the whole mixing system more reliable.

Comparison of Jingjin’s Mixers with Other Products:

- Sturdy Mixer Frames:Jingjin makes mixer frames by welding carbon structural steel. These frames are stronger than ones made from traditional cast iron.

- Long and Precise Stirring Shafts:Jingjin can make stirring shafts up to 13 meters long. They machine the flange and hub parts as one piece to keep everything centered. Other manufacturers can’t do this, so they end up with multi – section shafts that swing a lot at the ends.

- Acid – Resistant Stirring Shaft:The carbon steel rubber – lined stirring shaft works well in strong acid environments. It has an 8 – 10 mm thick layer of vulcanized butyl rubber. This rubber protects the main shaft from strong acids. It’s suitable for different materials when the temperature is below 90°C.