Agitator

For customized product solutions, please reach out to us!

Your satisfaction is our guarantee!

Jingjin will always be your reliable partner!

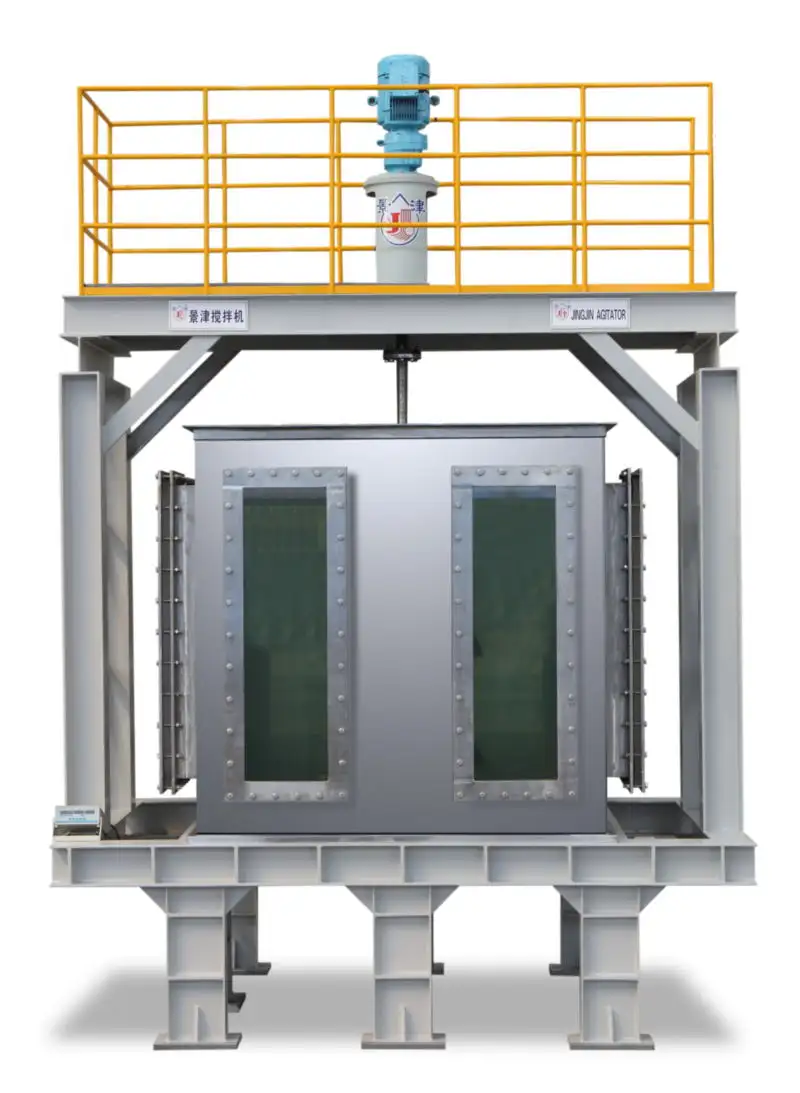

Introduction to Jingjin Agitator:

People use agitator widely in many industries, like chemical, pharmaceutical, food, mining, paper, paint, metallurgy, and wastewater treatment. Agitators are great for liquid-phase agitation tasks. They help with mixing different phases, such as liquid – liquid, liquid – solid, gas – liquid, and gas-liquid-solid combinations. They also assist with heat transfer, mass transfer, and chemical reactions. In our agitation test – bed, we match different trough types with agitators. We watch how the fluid actually moves during agitation and do data tests and collections. Based on this, we’ve improved the design and created new, useful propeller types. These new propellers can give the best agitation results while using the least power during full – load operation.

What are the application areas of Agitator?

Design Process of Jingjin Agitators:

Mixer Shaft

Food Industry Shaft

If you are interested in our products, please contact us !