How to Choose a Filter Press for Sludge Treatment That Meets South America’s Industrial Needs

Ago 11, 2025

Understanding the Role of a Filter Press in Sludge Management

In industries ranging from mining and metallurgy to food processing and municipal wastewater management, sludge treatment is a critical stage in waste handling. The filter press for sludge treatment is one of the most effective machines for separating solids from liquids, producing a dry, manageable cake and cleaner effluent. In South America, where diverse industries operate under varying climate conditions, the right filter press can significantly improve operational efficiency and compliance with environmental regulations.

Why South American Industries Need Efficient Sludge Treatment Solutions

South America’s industrial growth has accelerated demand for waste management solutions that are both efficient and cost-effective. Industrial plants in Brazil, Chile, Peru, and Argentina face stricter discharge standards, driving investment in high-performance filter press for sludge treatment systems. Selecting the right equipment means balancing performance with lifecycle costs, while considering region-specific factors such as energy availability, water scarcity, and maintenance resources.

Key Factors to Consider When Selecting a Filter Press

When evaluating your options, it’s important to go beyond the belt filter press price alone. A low upfront cost may seem attractive, but the total cost of ownership includes maintenance, spare parts, and energy consumption over the equipment’s lifetime. Working with an experienced filter press manufacturer ensures that the press you choose is engineered for your specific sludge type, volume, and operating environment.

Important evaluation points include:

- Material of construction – Stainless steel components, especially for plates and frames, offer better corrosion resistance in humid or chemically aggressive environments.

- Automation level – Fully automatic presses reduce labor costs and improve operational consistency, which is crucial in facilities with limited skilled manpower.

- Plate technology – Modern membrane plates and ultrahigh pressure designs enhance dewatering efficiency and cake dryness.

- Maintenance requirements – Choose models with easily accessible parts to minimize downtime.

Comparing Belt Filter Presses and Plate-and-Frame Presses

While belt presses are popular for continuous operations, plate-and-frame filter presses remain the gold standard for maximum solids capture and lowest moisture content. The choice depends on operational goals: if your priority is high throughput and lower operator intervention, a belt press might be suitable; if your goal is the driest cake possible for landfill disposal or reuse, a plate-and-frame system from a trusted filter press manufacturer may be the better investment.

| Type of Filter Press | Best For | Typical Cake Dryness (%) | Relative Price Range |

|---|---|---|---|

| Belt Filter Press | Continuous, medium-solids sludge | 18–25 | Moderate |

| Plate-and-Frame Press | High-solids, industrial sludge | 30–50 | Moderate–High |

| Membrane Plate Filter Press | Maximum dryness, reduced disposal costs | 35–55 | Higher |

Regional Service and Spare Parts Availability

For South American customers, the availability of local service and spare parts can be a deciding factor. Import delays or lack of technical support can lead to costly downtime. Partnering with a filter press manufacturer with regional distribution or service agreements ensures that both consumables and emergency repairs are handled quickly.

Balancing Price and Performance

The belt filter press price should be weighed against factors such as throughput, operating costs, and sludge disposal fees. A slightly higher initial investment in a machine with better dewatering performance can lead to substantial long-term savings, especially when landfill fees or environmental penalties are considered.

Why JingJin Filter is a Reliable Partner in South America

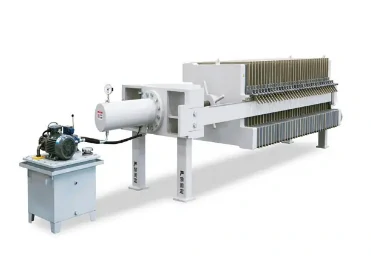

As a leading filter press manufacturer, JingJin Filter offers a range of solutions designed for industrial and municipal filter press for sludge treatment applications. Our presses are engineered for durability, with stainless steel and reinforced components suitable for the demanding environments often found in South American operations. We provide both belt and plate presses, ensuring clients can select the right technology for their needs and budget.

Our focus is not just on competitive belt filter press price, but on delivering value through high dewatering efficiency, reduced operating costs, and strong after-sales support. Whether you need a compact unit for a small municipal plant or a high-capacity press for mining slurry, we provide equipment that meets performance requirements while offering robust technical support.

Final Thoughts – Investing in the Right Filter Press

Choosing the right filter press for sludge treatment is not simply about finding the lowest belt filter press price—it’s about matching the right technology with your specific process and operational environment. South America’s diverse industries need solutions that are efficient, reliable, and supported locally. By partnering with an experienced filter press manufacturer like JingJin Filter, you ensure that your sludge management process delivers consistent results while complying with environmental standards.

Take the next step toward efficient sludge management—contact JingJin Filter today to discuss your project needs and get a tailored solution designed for your operation.