How Does Industrial Waste Water Pollution Affect Operations and How Can It Be Managed?

Gen 14, 2026

Industrial waste water pollution is one of the most pressing challenges for manufacturing, mining, chemical, and food processing industries. But what exactly is industrial waste water pollution, and how can companies manage it effectively while maintaining operational efficiency?

Industrial waste water pollution occurs when manufacturing or process effluents contain contaminants such as suspended solids, heavy metals, oils, or chemical residues that exceed environmental discharge standards. These pollutants, if untreated, can cause environmental damage, regulatory fines, and increased operational costs. Understanding the mechanisms of pollution and implementing proper treatment solutions is essential for sustainable industrial operations.

In this article, we will explore the sources of industrial waste water pollution, its operational impact, effective treatment methods including the use of industrial filter press systems, and how enterprises can turn compliance into operational value.

Sources and Types of Industrial Waste Water Pollution

Industrial waste water originates from diverse sources, depending on the industry and production processes. Typical contaminants include:

- Suspended solids: Slurry, sediments, or process by-products

- Dissolved chemicals: Acids, bases, salts, or organic compounds

- Oils and greases: Lubricants, process oils, or spills

- Heavy metals: Lead, cadmium, chromium, mercury

For example, in metal processing plants, sludge containing metal particles is a primary pollutant, while in food and beverage production, organic matter and oils dominate. Correct identification of pollutants is the first step toward designing effective treatment systems.

The Operational Impact of Waste Water Pollution

Unchecked industrial waste water pollution can affect operations in several ways:

- Regulatory penalties: Exceeding discharge limits can result in fines or shutdowns.

- Equipment fouling: Suspended solids can clog pumps, pipes, and filtration systems.

- Increased disposal costs: Untreated sludge may require costly handling or offsite treatment.

- Environmental liability: Contaminated discharge can harm ecosystems and corporate reputation.

By proactively managing waste water, companies not only avoid compliance risks but also enhance process reliability and long-term sustainability.

Key Technologies for Managing Industrial Waste Water Pollution

Several industrial treatment technologies address specific contaminants. Among them, filter press systems are widely used for solid-liquid separation due to their efficiency and scalability. A typical treatment process may involve:

- Sedimentation or clarification to remove coarse solids

- Chemical dosing to coagulate fine particles

- Filtration using industrial filter press systems for high-efficiency dewatering

- Optional polishing steps to meet strict discharge standards

For high-throughput industrial applications, the integration of advanced automation and monitoring ensures consistent performance and minimal downtime.

Comparing Waste Water Treatment Solutions

| Technology | Primary Function | Typical Industrial Application | Advantages |

|---|---|---|---|

| Sedimentation Tanks | Remove large suspended solids | Metal processing, pulp & paper | Low operational cost, simple design |

| Coagulation & Flocculation | Aggregate fine particles for easier removal | Chemical, mining | Improves filtration efficiency |

| Industrial Filter Press | High-pressure dewatering of sludge | Wastewater, chemical, food | High cake dryness, reduced disposal volume, recyclable filtrate |

| Membrane Filtration | Polishing and removing dissolved solids | Pharmaceutical, food & beverage | Produces high-quality effluent, compact footprint |

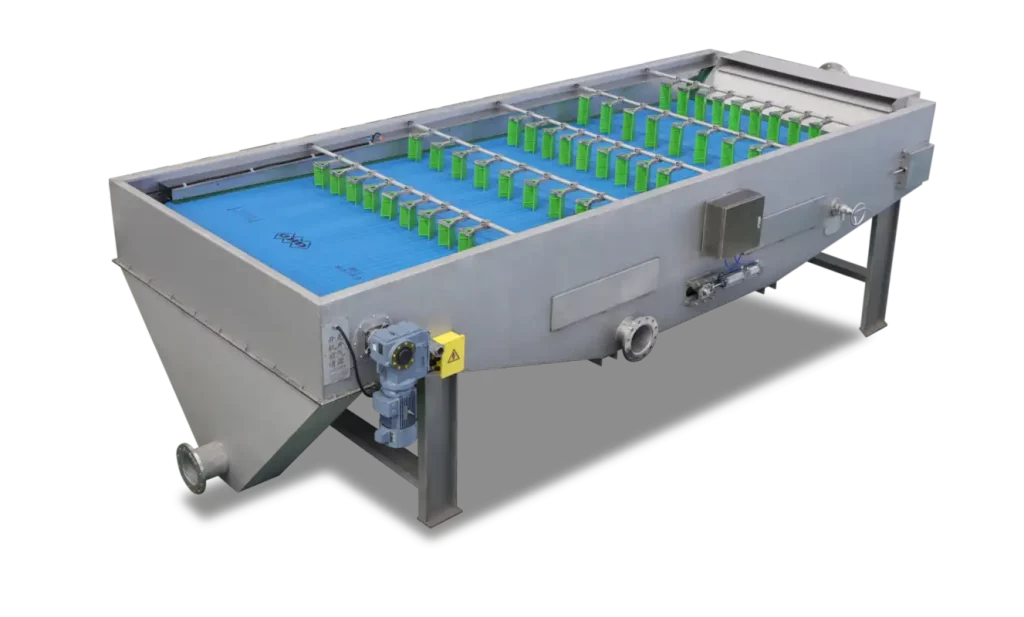

Advantages of Implementing a Filter Press System

Filter presses offer several benefits for industrial wastewater management:

- High solid capture efficiency: Produces a dense filter cake for reduced disposal costs.

- Customizable for diverse slurries: Plate and frame or membrane designs adapt to particle size and chemical properties.

- Enhanced operational reliability: Durable plates and cloths minimize maintenance and downtime.

- Environmental compliance: Meets discharge standards while reducing the environmental footprint.

For more insights into the advantages of wastewater management, industrial enterprises can explore case studies and ROI metrics.

Best Practices for Industrial Water and Wastewater Treatment

Efficient water and wastewater management is not limited to equipment selection. Companies should adopt a comprehensive strategy encompassing:

- Real-time monitoring of water quality

- Regular maintenance of filtration and pumping systems

- Optimization of chemical dosing and coagulation processes

- Integration with upstream and downstream operations

A holistic approach ensures sustainable performance and aligns with corporate environmental responsibility. Learn more about industrial water and wastewater treatment for modern industrial systems.

Looking to implement high-efficiency waste water treatment in your plant?

Contact Jingjin experts for tailored solutions.

FAQ: Industrial Waste Water Pollution

What is industrial waste water pollution?

It refers to contaminants in process or manufacturing effluents, including solids, chemicals, oils, and metals, that can harm the environment or exceed regulatory limits.

How does a filter press help?

A filter press efficiently separates solids from liquids, producing a dense cake and clean filtrate, reducing disposal costs and improving compliance.

How often should filter press plates or cloths be replaced?

Replacement frequency depends on slurry characteristics, operating pressure, and cleaning practices. Regular inspection extends service life.

Can industrial wastewater be fully recycled?

Advanced treatment systems can allow partial or full reuse, depending on contaminant levels and process requirements.

What industries benefit most from filter press treatment?

Mining, chemical, food & beverage, pharmaceuticals, and municipal wastewater treatment benefit significantly due to high-volume, solid-laden effluents.

Why Choose Jingjin for Industrial Waste Water Solutions

Jingjin is a global leader in industrial filter press design and manufacture, offering complete solutions for solid-liquid separation. Our systems are tailored for diverse industrial applications, from chemical plants to municipal wastewater treatment, and include fully automated, high-capacity filter presses with robust plates and high-performance cloths.

With decades of engineering expertise, quality assurance, and global service support, Jingjin helps enterprises achieve reliable filtration, operational efficiency, and compliance with environmental regulations.

References

- Wikipedia – Industrial wastewater: https://en.wikipedia.org/wiki/Industrial_wastewater

- ScienceDirect – Wastewater treatment technologies: https://www.sciencedirect.com/topics/engineering/wastewater-treatment

- Filtration Industry Analyst – Industrial filter press applications: https://www.filtnews.com/articles/industrial-filter-press-usage