What Is an Agitator Tank Used For in Industrial Processing?

Juil 15, 2025

While using annual industrial processes, the most important part is efficient mixtures such as chemical blending, slurry stabilisation, or improving performance through filtering. The Agitator Tank is the place of the most important work. It is specially designed to thoroughly mix solids and liquids, and is therefore placed in locations such as wastewater treatment, mining, food processing, pharmaceuticals, and the like.

Through the use of JingJin Filter’s filter press wastewater treatment systems and customized JINGJIN filter plates, the Chinese Agitator Tank will be part of the solid-liquid separation technologies of JingJin Filter. This consolidation results in a system where the applied stirring and the deposit suspension cleaning, flow control, and the pre-filtering process supply reliability together, providing a harmonious and unbreakable order.

What Is an Agitator Tank?

An agitator tank is a sealed or open container equipped with a mechanical mixing device, such as an impeller, paddle, or turbine. These components rotate at varying speeds to ensure that fluids and solids are thoroughly mixed, preventing separation or sedimentation.

In wastewater treatment applications, the China Agitator Tank is often used before filtration. It helps maintain the homogeneity of the sludge or slurry so that when it reaches the press stage—such as a filter press wastewater treatment system—the material is consistently conditioned for optimal separation.

Benefits of Using JingJin’s Agitator Tanks in Filtration Workflows

- Improved Solid Suspension: Prevents solids from settling, which enhances filter press efficiency

- Enhanced Mixing Uniformity: Ensures consistent concentration of slurry across batches

- Supports Chemical Reactions: Ideal for pH adjustments and flocculant distribution

- Corrosion Resistance: Materials like stainless steel and FRP for chemical compatibility

- Custom Integration: Easily connected with JINGJIN filter plates and press systems

Combining Agitation and Filtration for Better Results

One of the most valuable applications of the Agitator Tank is in pre-treatment stages of filter press wastewater treatment. Proper mixing ensures that the slurry sent to the filter press is neither too dilute nor too thick. This balance increases cake dryness and shortens press cycles.

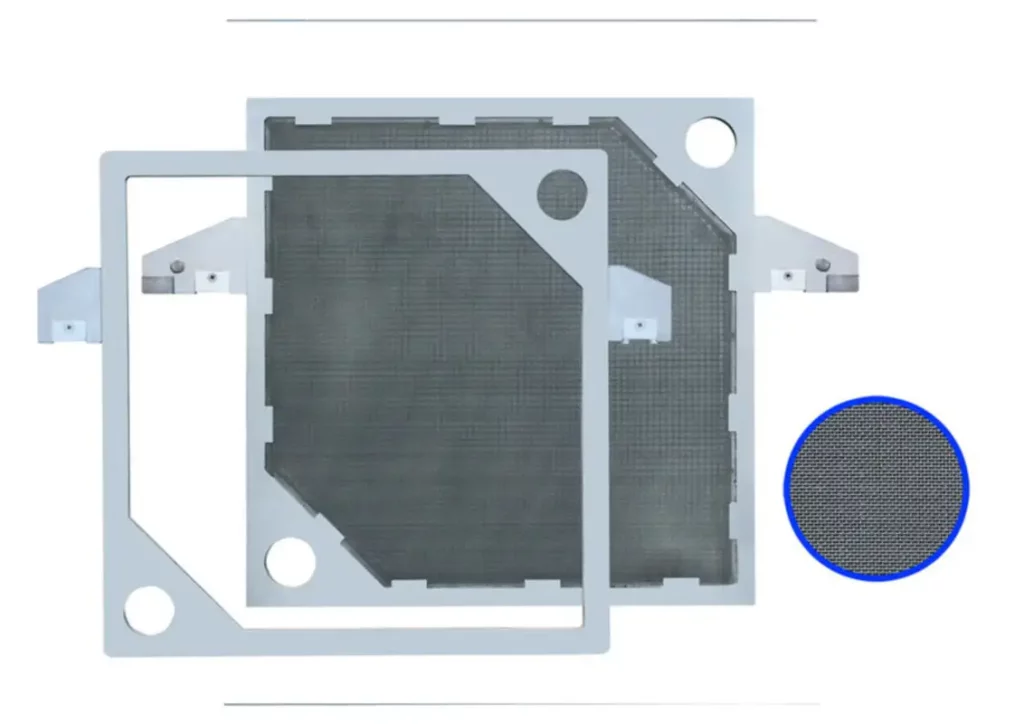

JingJin Filter offers tanks that are precisely calibrated to match the flow rate, solid content, and pH level of the incoming material. Their designs also take into account the compatibility with JINGJIN filter plates, which are engineered for specific pore sizes, pressure tolerances, and discharge methods.

These tanks are especially beneficial in industries with variable feed characteristics. Whether you’re filtering textile dyes, mining effluent, or food-grade slurries, a China Agitator Tank ensures your system stays consistent and efficient.

Why Choose JingJin Filter?

With over 30 years of industry expertise, JingJin Filter is not just a filter press manufacturer—they are a system integrator. Their agitator tanks are:

- Designed to match their filter press wastewater treatment systems

- Made with durable materials that resist abrasion and corrosion

- Supported by a global logistics and installation network

- Optimized for use with JINGJIN filter plates, enhancing throughput and press cycle control

- Available in multiple volumes and configurations, from 500L to 10,000L+

This seamless integration reduces maintenance, improves solid capture, and ensures each filtration cycle is as productive as possible.