Filter Cloth Selection: Maximizing Efficiency in Industrial Filtration

Oct 13, 2025

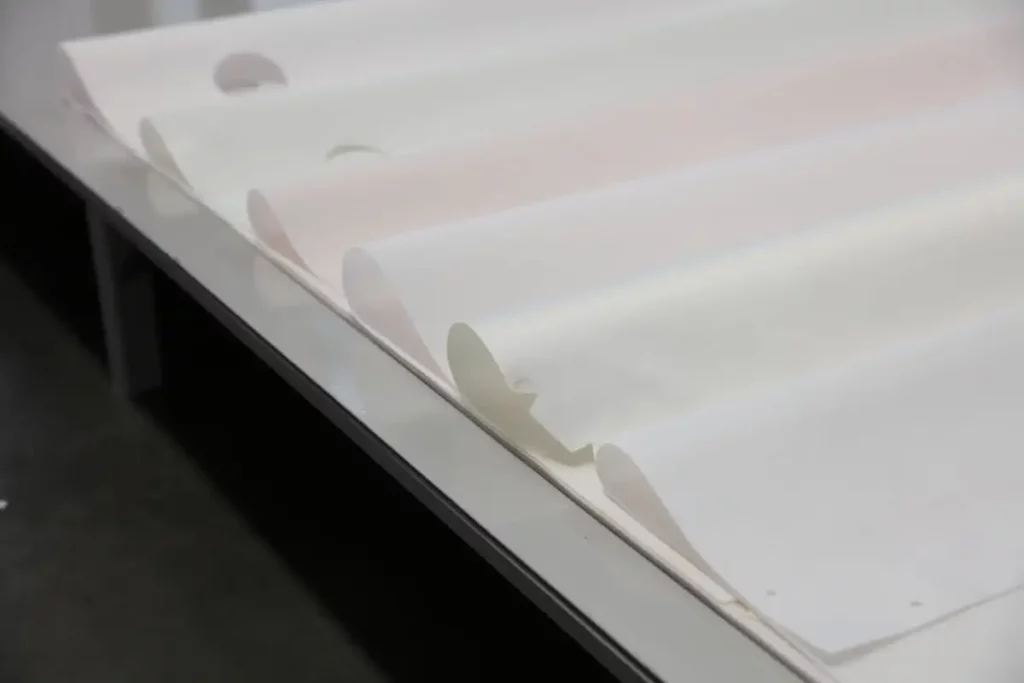

Why Choosing the Right Filter Cloth Matters

For industries in Central and South America—including mining, chemical processing, and wastewater treatment—the efficiency of an industrial filter press depends heavily on the filter cloth used. The right filter cloth ensures optimal solid-liquid separation, reduces cake moisture, and extends equipment lifespan. Poorly chosen cloth can result in frequent blockages, uneven filtration, and increased downtime, directly affecting productivity and operational costs.

Key Factors in Filter Cloth Selection

Selecting the ideal filter cloth requires considering material, weave type, and chemical compatibility. Common materials include polypropylene, polyester, and cotton blends. Each offers distinct advantages:

- Polypropylene: Resistant to acids, alkalis, and moisture; suitable for chemical industries.

- Polyester: Strong and durable; ideal for abrasive slurries and high-temperature applications.

- Cotton Blends: Flexible and cost-effective for lighter-duty applications.

Weave patterns—such as twill, plain, or satin—affect cake release and filtration rate. Choosing the right combination ensures maximum throughput while maintaining product quality.

Impact on Operational Efficiency

The filter cloth plays a critical role in the cycle time and maintenance schedule of a industrial filter press. A well-selected cloth minimizes blockage, reduces cleaning frequency, and prevents slurry leakage. Additionally, it helps achieve lower moisture content in the filter cake, reducing disposal costs and improving resource recovery. For mills and plants in Latin America, where efficiency and cost management are key, this translates directly into higher profitability.

Custom Solutions for Industry-Specific Needs

Different industries and processes have unique filtration requirements. For example:

- Mining: Abrasive and high-solids slurries demand high-strength, durable cloth.

- Food and Beverage: Hygiene and easy cleaning are critical; cloth must meet regulatory standards.

- Chemical Processing: Cloth must resist corrosive chemicals and high temperatures.

Working with an experienced supplier ensures that the selected Filter Cloth matches process conditions, enhancing performance and equipment longevity.

Jingjin — Your Partner for Reliable Filtration Solutions

Jingjin is a leading provider of high-quality industrial filter press systems and Filter Cloth solutions, serving clients worldwide. With decades of expertise, Jingjin offers customized filtration systems designed to optimize efficiency, reduce downtime, and increase overall production quality. Our durable filter cloths and engineered presses are trusted by industries across Central and South America to meet the most demanding operational challenges.

Explore our range of industrial filter press solutions today to discover how Jingjin can help your plant achieve superior filtration performance and cost-effective operation.