Can a Plate and Frame Type Filter Press Reduce Operational Costs in Filtration?

Aug 18, 2025

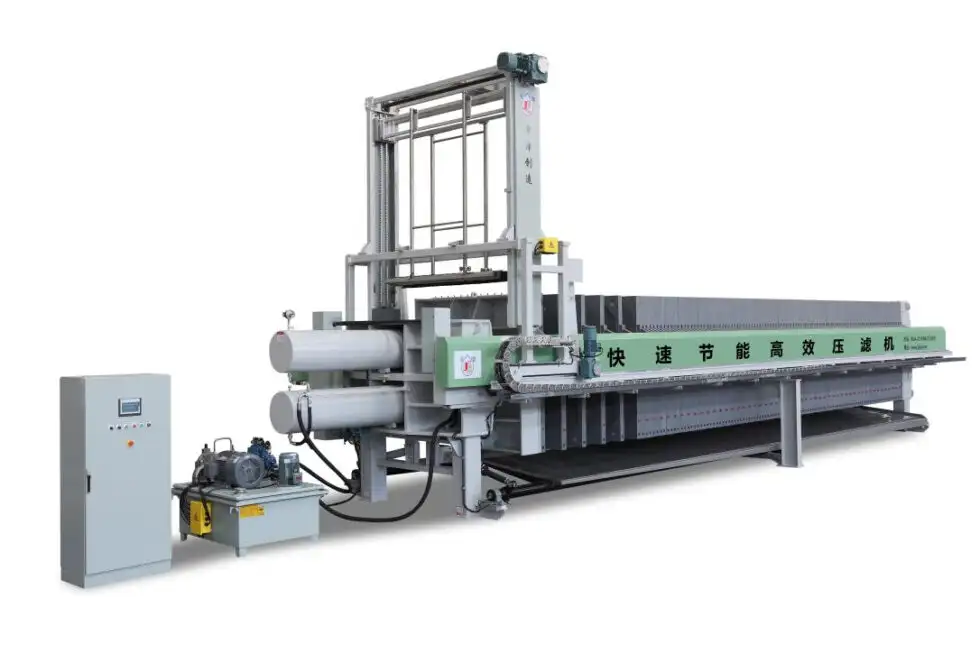

In industries where solid-liquid separation is critical, efficiency and cost savings drive decision-making. From mining to food processing, businesses need reliable equipment that can lower energy consumption, minimize waste, and ensure consistent output. Among the many filtration technologies available, the Plate and Frame Type Filter Press continues to be a dependable choice for companies seeking both performance and affordability.

How the Plate and Frame Type Filter Press Works

A Plate and Frame Type Filter Press operates by applying pressure to separate liquids from solids. The slurry is pumped into chambers formed by alternating plates and frames, where a filter cloth captures solid particles while allowing filtrate to pass through. This design, one of the earliest types of filter presses, has proven itself as simple yet highly effective.

Its modular nature allows manufacturers to adjust plate sizes, the number of frames, and filter cloth types based on application needs. As a result, the plate and frame system remains versatile in industries such as chemicals, pharmaceuticals, food and beverage, and wastewater treatment.

Reducing Operational Costs

The key question is whether a Plate and Frame Type Filter Press can truly reduce costs. The answer lies in three main areas:

- Lower energy consumption – Mechanical pressure-driven filtration consumes less energy compared to thermal drying or evaporation.

- Reusable filter cloths – Properly maintained cloths can be used repeatedly, reducing replacement expenses.

- Long equipment lifespan – These presses are known for durability, requiring relatively low maintenance compared to other systems.

In operations where budget efficiency is crucial, this type of press provides a cost-effective balance of performance and reliability.

Comparing with Membrane Filter Press Technology

While the Plate and Frame Type Filter Press is highly effective, modern facilities are also adopting the Membrane Filter Press for greater efficiency. Membrane presses incorporate flexible membranes that can be inflated to apply additional squeezing force to the filter cake, resulting in drier solids and shorter cycle times.

However, membrane systems typically come with a higher initial investment. For plants prioritizing long-term savings and enhanced dryness of solids, membrane presses may be preferable. On the other hand, the Plate and Frame system remains attractive for its simplicity, lower cost, and adaptability to a wide range of materials.

Benefits of Filter Presses in General

Whether it is a traditional plate and frame system or an advanced membrane model, filter presses offer benefits that directly translate into operational savings:

- High solid recovery – More efficient separation reduces waste.

- Improved water recycling – Captured filtrate can often be reused in processes.

- Lower disposal costs – Drier filter cakes mean reduced weight and volume of waste.

- Scalability – Systems can be expanded or customized for different capacities.

These benefits are why filter presses remain a cornerstone of industrial filtration technology.

JingJin Filter: Innovation and Reliability

As one of the world’s leading filtration equipment manufacturers, JingJin Filter offers a complete range of filtration solutions, from the Plate and Frame Type Filter Press to advanced Membrane Filter Press systems. With decades of experience and global reach, JingJin has become a trusted name for industries that demand reliable separation technology.

JingJin’s equipment stands out for:

- Precision engineering – Designed to maximize efficiency and reliability.

- Comprehensive product range – Covering traditional and advanced filter press models.

- Commitment to sustainability – Supporting clients in reducing waste and reusing resources.

By combining innovation with proven designs, JingJin helps businesses strike the right balance between cost savings and high performance.

The Future of Filtration Efficiency

As industries face increasing environmental regulations and rising operational costs, filtration systems will continue to play a vital role in sustainable production. While the Plate and Frame Type Filter Press remains a cost-saving solution for many, advanced models like the Membrane Filter Press are pushing the boundaries of efficiency.

With companies like JingJin Filter at the forefront, businesses can expect filtration solutions that reduce costs while meeting environmental and operational demands.

Optimize Your Filtration with JingJin Filter

For cost-effective, reliable solid-liquid separation, choose Plate and Frame Type Filter Presses, Membrane Filter Presses, and other advanced filter presses from JingJin Filter. Contact JingJin today to explore tailored solutions that reduce operational costs and boost efficiency.