Industrial Water and Wastewater Treatment: Building Efficient, Compliant, and Sustainable Systems for Modern Industry

Jan 4, 2026

Why Industrial Water and Wastewater Treatment Is a Strategic Investment, Not a Cost

Industrial water and wastewater treatment has become a strategic priority for manufacturers operating in an increasingly regulated and resource-constrained environment. Across industries such as chemicals, metallurgy, food and beverage, pharmaceuticals, mining, power generation, and textiles, water is both a critical production input and a major source of operational risk. Poorly managed water systems can lead to rising costs, production instability, regulatory penalties, and reputational damage, while efficient treatment systems create measurable business value.

Unlike municipal treatment, industrial water and wastewater treatment must address highly variable influent quality, fluctuating volumes, and industry-specific contaminants. This complexity means that treatment systems are no longer designed solely for discharge compliance. Instead, they are engineered to support process stability, water reuse, and long-term operational flexibility. For B2B decision-makers, investing in the right treatment strategy is a way to protect assets, improve efficiency, and strengthen competitiveness in global markets.

As water scarcity intensifies and environmental regulations tighten, industrial enterprises that treat water management as a core operational function rather than an auxiliary utility gain a clear advantage. Effective treatment systems allow companies to plan production with confidence, respond to audits without disruption, and align environmental performance with business growth objectives.

Cost Control, Water Reuse, and Operational Efficiency

One of the most compelling reasons industrial enterprises invest in advanced water and wastewater treatment systems is cost control. Freshwater intake, wastewater discharge fees, chemical consumption, and maintenance expenses all contribute to the total cost of water management. Inefficient systems often result in excessive water use, frequent equipment fouling, and unplanned downtime, which can quietly erode profitability.

Modern industrial water and wastewater treatment focuses on maximizing water reuse and minimizing waste generation. By treating process water to a reusable standard, companies can significantly reduce freshwater dependency and stabilize operating costs, particularly in water-stressed regions. This approach aligns closely with the broader advantages of wastewater management, where effective treatment transforms wastewater from a liability into a managed resource that supports production continuity and cost predictability.

In addition to direct savings, efficient treatment systems improve operational efficiency across the plant. Stable water quality protects downstream equipment, reduces scaling and corrosion, and extends the service life of pumps, heat exchangers, and production machinery. For B2B operators, these indirect benefits often deliver a return on investment that exceeds initial expectations.

Regulatory Compliance and Risk Reduction in Industrial Operations

Regulatory compliance is a non-negotiable driver of industrial water and wastewater treatment. Environmental authorities worldwide are enforcing stricter discharge limits on parameters such as COD, BOD, suspended solids, heavy metals, and toxic compounds. Non-compliance can result in heavy fines, forced shutdowns, or loss of operating permits, all of which pose serious business risks.

A robust treatment system provides industrial enterprises with control and transparency over their wastewater streams. Continuous monitoring, standardized processes, and documented performance data enable companies to demonstrate compliance during inspections and audits with confidence. This is particularly important for exporters and multinational manufacturers, where environmental performance increasingly influences supplier qualification and long-term contract decisions.

From a risk management perspective, proactive treatment design is far more effective than reactive responses. Systems built with redundancy, scalability, and process flexibility allow plants to handle fluctuations in load or influent quality without violating discharge standards. For B2B decision-makers, this level of risk reduction is a key factor in safeguarding both operational continuity and corporate reputation.

Technology Selection and the Role of Advanced Filtration

The performance of industrial water and wastewater treatment systems depends heavily on technology selection. Because industrial effluents vary widely in composition and concentration, treatment solutions must be tailored to specific process requirements rather than relying on generic designs. Mechanical separation, chemical treatment, biological processes, and advanced filtration technologies all play a role in modern systems.

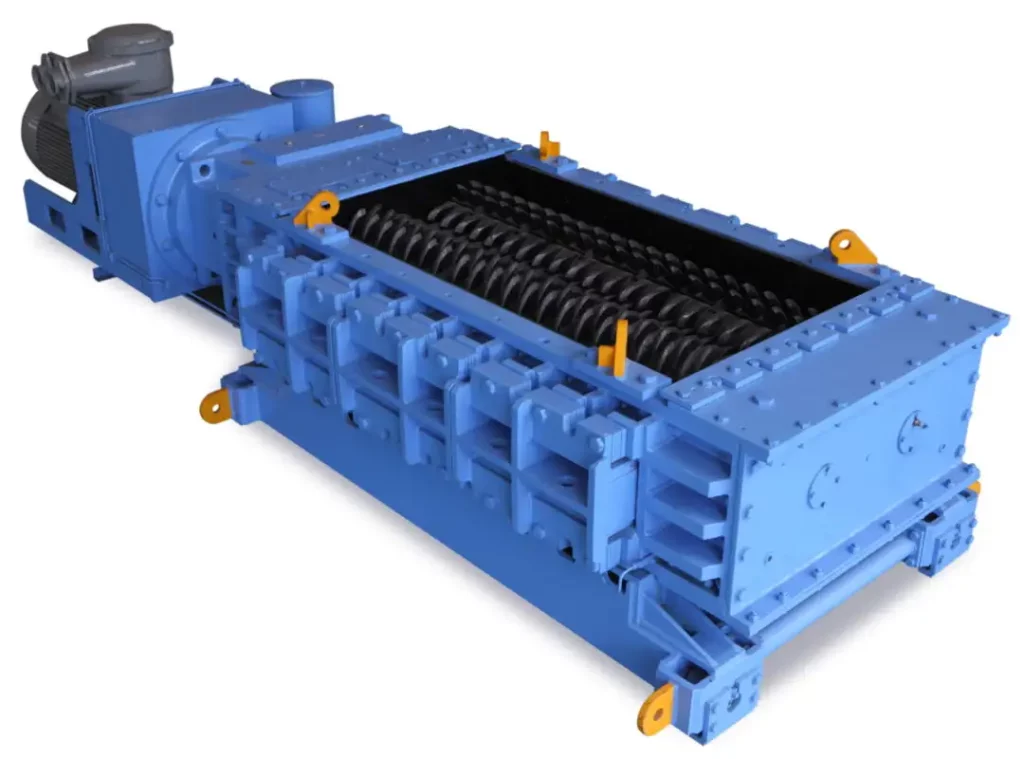

Among these, industrial filtration solutions are central to achieving reliable solid-liquid separation and consistent effluent quality. High-performance filtration equipment improves dewatering efficiency, reduces sludge volume, and supports downstream treatment processes. When properly integrated, filtration systems help industrial plants achieve stable operation with lower energy consumption and reduced chemical usage.

Choosing the right technology partner is equally important. Experienced suppliers provide more than equipment; they offer process insight, system optimization, and lifecycle support. For B2B buyers, collaboration with knowledgeable partners ensures that treatment systems remain effective as production demands, regulations, and sustainability goals evolve over time.

Sustainability, ESG Goals, and Long-Term Business Resilience

Sustainability has become a defining factor in industrial investment decisions, driven by ESG frameworks, investor expectations, and customer requirements. Industrial water and wastewater treatment plays a central role in achieving sustainability targets by reducing environmental impact and promoting responsible resource use.

Effective treatment systems minimize pollutant discharge, protect local ecosystems, and enable water reuse within industrial processes. These outcomes support circular economy principles and strengthen corporate sustainability reporting. For many B2B enterprises, strong environmental performance is no longer just a compliance issue but a market differentiator that influences customer trust and brand value.

Beyond environmental benefits, sustainable water management enhances long-term business resilience. Facilities with efficient treatment systems are better prepared to adapt to regulatory changes, water scarcity, and production expansion. This adaptability allows enterprises to grow responsibly while maintaining control over environmental and operational risks.

About Jingjin

At Jingjin, we specialize in industrial water and wastewater treatment solutions that help enterprises achieve efficiency, compliance, and sustainability. As a professional filtration equipment manufacturer and solution provider, Jingjin delivers advanced solid-liquid separation and filtration systems designed for demanding industrial applications. Our focus on engineering reliability, process optimization, and long-term service enables B2B customers to reduce operating costs, improve treatment performance, and build resilient water management systems that support sustainable growth and global competitiveness.