How Is Membrane Filter Press Changing the Game of Traditional Equipment?

Jun 25, 2025

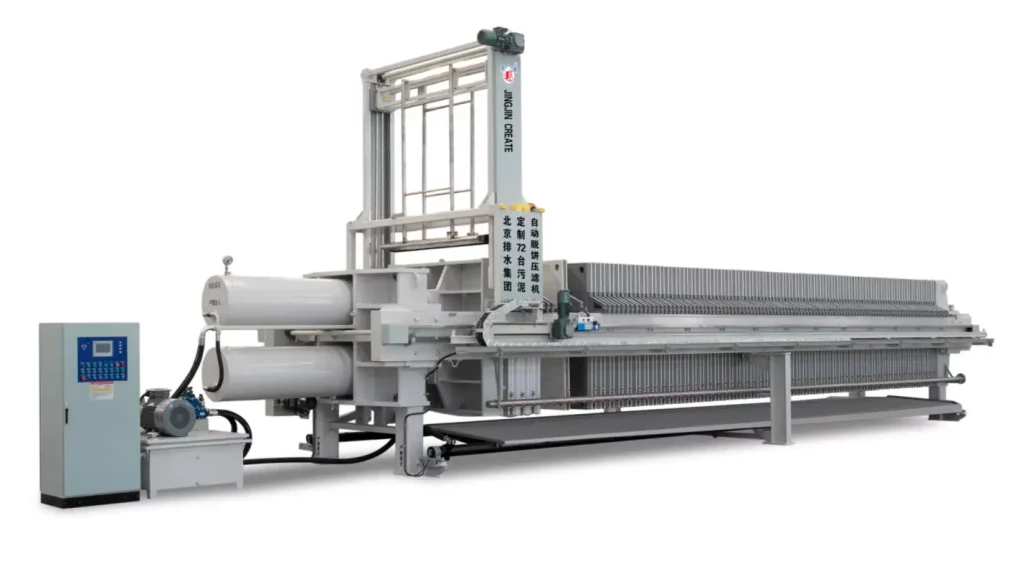

In the rapidly changing space of the industrial filtration, the choice of equipment plays a major role in the efficiency, quality, and environmental footprint of the process. Among the numerous tools available, a membrane filter press is recognized as the best in comparison to the traditional filter press. The paper is about the highlighted differences between membrane filter presses and conventional filters, which covers reasons why the companies are advised to use the Jingjin filter press for their filtration purposes.

Understanding Membrane Filter Press Technology

A membrane filter press is equipped with a new method that greatly increases the efficiency of the filtration process. In the case of traditional filter presses, the method of separation of solids from liquids was based only on gravity and pressure, but, in the membrane method, an elastic membrane is used other than a filter press which plays a key role in the process. The membrane is fixed between the filter plate and the filter cloth.

After the feeding phase, a very high-pressure liquid that is directed to the diaphragm plate is an essential step of the process. In this way, the plate is inflated and through its force, the pressure on the filter cake is augmented that leads to an efficient water removal from the cake and as a result, the levels of water remaining are decreased. This is what people know as the squeeze filtration process, the principle of which lies in the fact that the air and the water will be separated.

Key Advantages of Membrane Filter Presses

- Higher Efficiency: Membrane filter presses achieve a much higher pressing pressure than traditional equipment. This results in a more efficient separation process, allowing for greater throughput and reduced processing times.

- Lower Moisture Content: One of the most significant advantages of using a membrane filter press is its ability to reduce the moisture content of the filter cake. Traditional chamber filter presses may leave moisture levels above 70%, while membrane presses can lower this to below 60%. This reduction not only decreases transportation costs but also allows for easier disposal or incineration of the filter cake.

- Enhanced Corrosion Resistance: The materials used in Jingjin filter presses are designed to withstand harsh chemical environments. This durability ensures a longer lifespan and reduces maintenance costs compared to traditional filter presses, which may corrode over time.

- Automatic Operations: Many modern membrane filter presses, including those from Jingjin, feature automatic operations such as cloth washing and plate shifting. This automation minimizes manual intervention, enhancing operational efficiency and reducing labor costs.

- Versatile Applications: Membrane filter presses are highly adaptable and are used across various industries, including pharmaceuticals, food and beverage, metallurgy, and environmental protection. They excel in applications requiring solid-liquid separation, making them a preferred choice for many sectors.

Have any other questions? Welcome to contact us, we will serve you wholeheartedly!

Membrane Filter Press vs. Traditional Chamber Filter Press

- Comparing membrane filter presses and conventional chamber filter presses makes several fundamental differences obvious:

- Performance of Filtration: The components of the membrane filter press have greater strength to apply more pressure through the membrane, which gives a product of higher quality and a drier filter cake.

- Cost Efficiency: Though the first cost of a membrane filter press might be more, the overall benefits received from the lessening of moisture content, decreasing disposal costs, and reducing maintenance expenses suggest them as a more efficient choice for shredding the budget.

- Environmentally Friendly: The fact that membrane filter presses do two things at once firstly, make sludge resources and secondly, reduce the amount of waste is in accordance with initiatives for the environment protection and resources recovery that are global in their nature.

Why Decide on Jingjin Filter Press?

As a key filter press supplier, Jingjin has become a reputable brand in the industry. Established in 1998, Jingjin has as its major production agenda the output of top-grade filtration equipment coupled with excellent customer solutions. Jingjin, by sticking to high standards of service and product-reaching innovation, has to its credit the constant highest production and sales of filter presses all over the globe.

Summary

In the final analysis, the membrane filter press is undeniably miles ahead of conventional filtration tools. The process of optimizing efficiency and energy conservation, reducing humidity, and standing firm in the face of severe climatic conditions are the very things that make the machine quite suitable for a multitude of businesses. Whenever a purchase of a filter press is in mind, the ideal location from where to get the most innovative pieces of equipment combined with unswerving dedication to the customer is Jingjin filter presses.

For personalized product solutions or to inquire further on how a Jingjin filter press can support your operations, please contact us. Your contentment is our assurance and Jingjin is your always trustworthy partner!