What to Look for in an Agitator Tank?

Jul 22, 2025

From chemical processing to mineral separation, efficient mixing is the starting point of any reliable filtration system. At the center of this process lies the agitator tank—a deceptively simple yet essential component that determines whether your filtration equipment runs efficiently or struggles with inconsistent output.

For industries relying on high-throughput solids-liquid separation, such as those using a Vacuum filter press, choosing the right China agitator tank is not just about volume—it’s about engineering compatibility, energy efficiency, and material handling precision.

Agitation Is More Than Just Mixing

Agitator tanks are more than only containers with big blades that are just rotating. In filter press china plants with high performance levels, they are well-constructed utensils that are responsibly designed to mix the ingredients accurately with the help of certain speed, torque, and duration. This is very important because unsatisfactory mixing results in non-uniform slurry, which in turn, not only causes filtration inefficiency but also leads to clogged filter plates and shortened equipment life.

Modern agitator tanks—especially those produced in China—now offer variable-speed motors, precision impeller design, and sealed drive systems to support both open and closed-loop processing. In systems where vacuum is involved, such as a Vacuum filter press, pressure integrity must be maintained throughout agitation and transfer.

A Good Agitator Tank Should Offer More Than One Function

Rather than just stirring, today’s best tanks are multi-functional pre-treatment units that support:

- Suspension of heavy particles and preventing settling at the tank bottom

- Homogenization of multi-phase solutions before filtration

- pH adjustment or dosing of reagents

- Heat transfer via internal coils for thermal control

Choosing a China agitator tank with these features allows the entire filtration line—especially in large-scale systems with a filter press china setup—to operate with less maintenance, better throughput, and consistent output quality.

Engineering Quality Matters

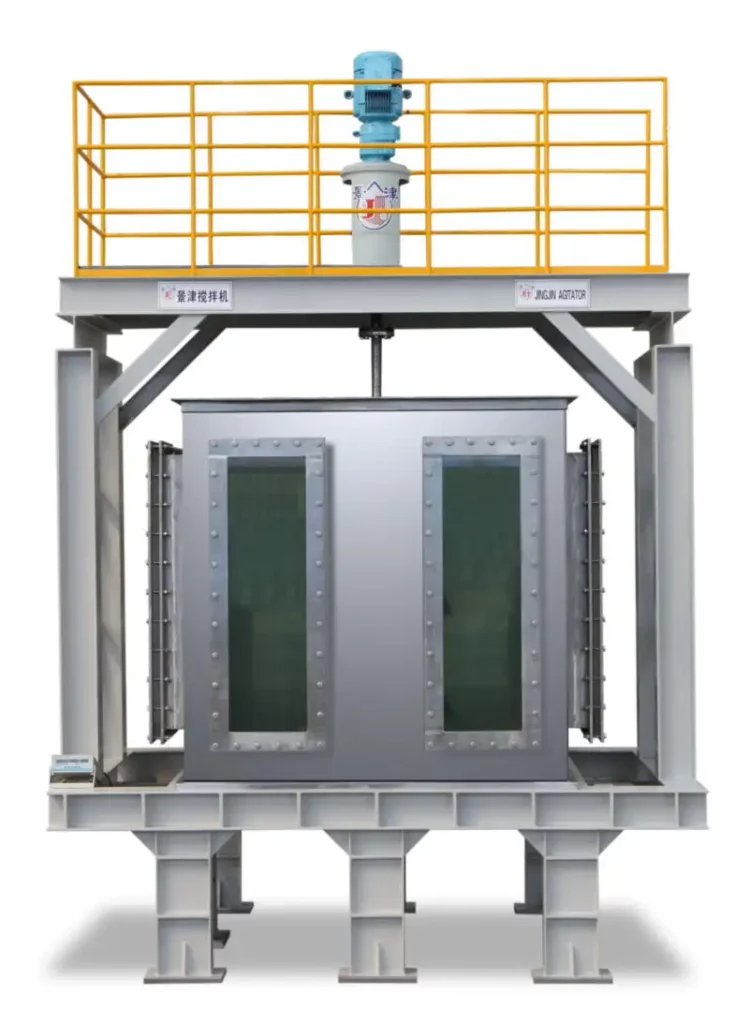

One of the most overlooked aspects of an agitator tank is how well it integrates into an existing processing line. Tanks must be designed to handle slurries of varying viscosities, aggressive chemicals, and sharp particle edges. This is where JingJin Filter brings a decisive advantage.

With decades of experience as a trusted filter press china manufacturer, JingJin’s tanks are fabricated using corrosion-resistant alloys and offer several impeller configurations—pitch blade, turbine, anchor, or customized hybrid designs—to match process demands.

JingJin’s agitator tanks are built to maintain uniform consistency during batch mixing and continuous feed, ensuring no “dead zones” or material build-up. Whether you’re feeding into a Vacuum filter press or a plate-and-frame system, a consistent slurry mix is vital.

What to Ask Before You Buy

Before committing to an agitator tank purchase, consider asking the following:

- Does the tank allow for easy cleaning and maintenance, especially between batches?

- Can the motor drive adjust speed and torque depending on viscosity changes?

- Is the tank rated for vacuum or pressure environments if connected to sealed systems?

- What certifications does the tank meet—ISO, CE, or industry-specific codes?

A reliable China agitator tank should answer all these with confidence—and ideally come from a supplier with proven expertise in integrated systems.

Why JingJin Filter Is a Smarter Choice

As opposed to creating general-purpose tanks, JingJin Filter designs agitator tanks that are compatible with its popular filter press china series, a situation that results in enhanced performance and quicker installation. The company’s extensive knowledge in liquid-solid separation allows the installation of every Vacuum filter press system with a tank, which is tailored to the specific requirements of each customer for optimizing input flow rate, consistency, and agitation dynamics.

Clients across industries—mining, municipal wastewater, ceramics, metallurgy—rely on JingJin for complete filtration ecosystems, not just standalone components. The result is reduced downtime, improved operational control, and greater ROI.