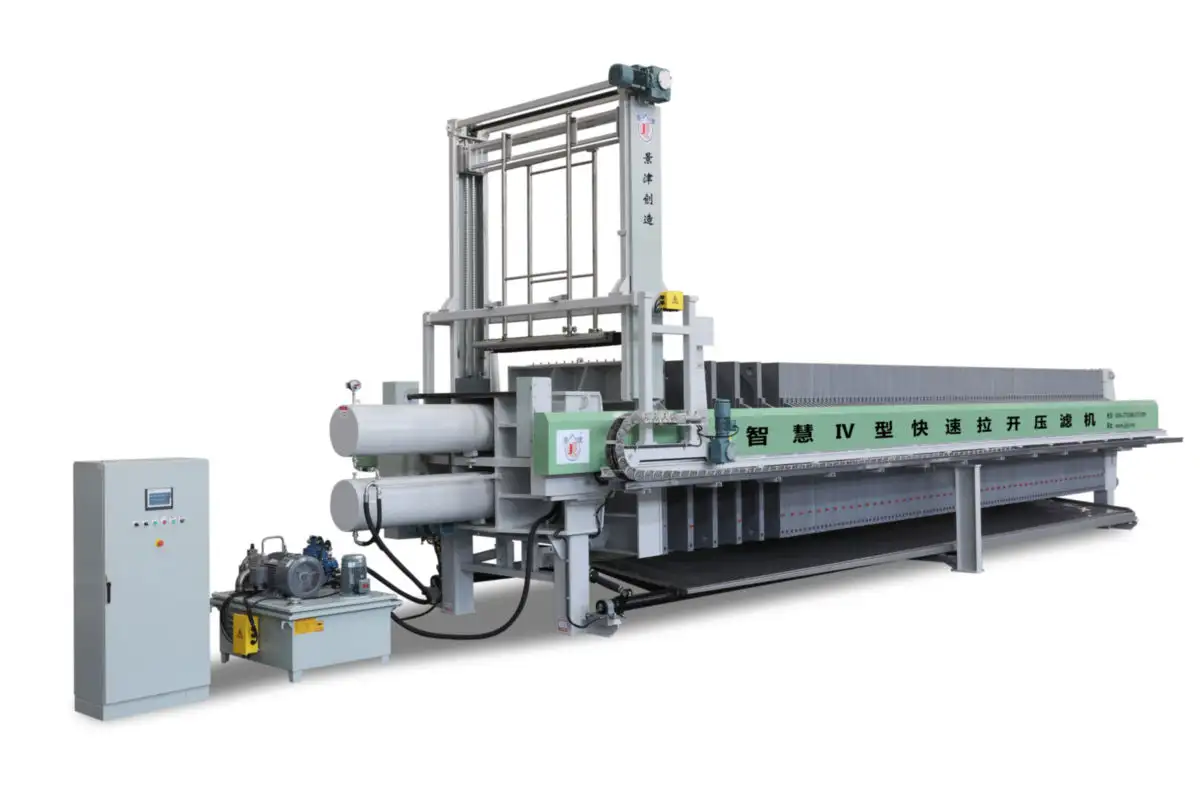

Quick Details of Tube Press Filter

Our Tube Press Filter details are as below:

| Condition: | New |

|---|

| Automatic Grade: | Automatic |

| Production Capacity: | High efficiency |

| Voltage: | 3ph/380V50HZ.3ph/415V/50HZ, 3ph/440V/60HZ. or other |

| Power: | Total 9.55kw |

| Weight: | 3400KG |

| Dimension(L*W*H): | 5100*1500*1360 |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Certification: | CE,ISO9001:2008 |

| Plate shifting method:: | Automatic shifting one by one |

| Feeding method:: | Single and center feeding |

| Power type: | Automatic hydraulic press and open |

| Cloth washing: | Automatic cloth washing one by one |

| Drip tray: | Auto open and close, carbon steel , stainless steel |

| Color: | Blue, Yellow, Green, White, Grey, Brown,etc |

What are the advantages of Tube Press Filter?

- High-efficiency solid-liquid separation: Tubular filter presses can use pressures up to 100 bar. This high pressure helps separate solids and liquids more thoroughly. Even with ultra-fine slurries, they can make dry filter cakes while using less energy.

- Easy maintenance: There are only a few moving parts, so it’s not hard to maintain these filter presses.

- Automated operation: They work fully automatically, which boosts efficiency and keeps the results consistent.

- Very high filtrate clarity: The filtration process works really well, so the filtrate comes out very clear.

- High cake solids content: Compared to low-pressure filters, tubular filter presses make filter cakes with smaller pores and less moisture. That means the cakes end up drier.

- High filtration flux: Tubular filter presses can filter dry solids at a much faster rate per unit area than vacuum or regular filter presses. This is because the filtration rate depends on pressure, and these presses can work under the best filtration conditions.

![]()

![]()

Introduction of Advanced German Equipment by JINGJIN

Jingjin focuses on energy conservation and environmental protection. It offers customers affordable products and great services. To meet tough filtration needs, Jingjin brought in a full set of

German filter cloth production lines and technology.

With 27 years of filtration experience, Jingjin uses strong German rapier looms. These looms weave the best silk threads into high-density filter cloths with different hole patterns. After each weft crosses the warp, they apply a beating-up force of 0.3-3.5 tons. Jingjin’s filter cloths have 50% more filtration holes per unit area than others, so they filter much faster. The company weaves the cloth in controlled temperature and humidity to stop static electricity from creating fabric burrs.

One of the biggest innovations is that Jingjin’s monofilament filter cloth makes filter cakes fall off automatically. This solves a problem that has troubled the industry for a long time.

![]()

Workshop Show

![]()