How to Reduce the Operating Cost of Sludge Filter Press?

May 28, 2025

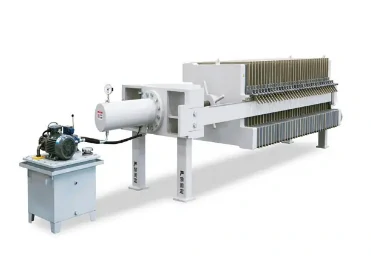

Wastewater treatment industries consider managing operational costs as the main goal for their sludge filter presses. These machines are very important in solid-liquid separation, but their efficiency and cost-effectiveness are dependent on many factors.In the article practical solutions for: selecting the right equipment, process optimization, maintenance management, energy consumption, and resource recovery are presented as a means to deal with the matter about the reduction of the operating costs of sludge filter presses.

1. Accurate Equipment Selection

Shop for Machines Matching Sludge Types

High-Viscosity Sludge: Industries like food processing and pharmaceuticals can utilize a membrane filter press to achieve better dewatering effectiveness and less processing time, about 20%-30% reduced.

High-Sand Content Sludge: The utilization of plate and frame filter press with long-lasting filter cloths is the best thing to do in mining and sand washing. This configuration eliminates wear and tear extending up to 6,000 hours the service life of filter cloths.

Main criteria

Filtration Area: You can calculate the required filtration area by using the formula Processing Volume = Filter Area × Sludge Concentration × Dewatering Efficiency.

Operating Pressure: For the better operation of a municipal sludge filter press standard pressure is generally within the range of 8-12 MPA, industrial sludge might require the pressure of about Ц PMА. Inadequate pressure equipment (the separation of the sludge from water)may contribute to higher water content and as a result more solid waste to dispose off.

2. Optimize Processes to Reduce Consumption

Dosing of Polymer

Selecting the right flocculant through conducting a laboratory-based surface to the sludge can lead to efficient use of polymer (such as Polymer Acrylamide (PAM) and Polyaluminum Chloride (PAC)) and his small change in the amount of polymer usage can instantly lead to a significant reduction in costs that can amount to 5 to 8% per tonne of the sludge.

Enhance Dewatering Procedures

One of the ways in which the clogging of the filter media can be prevented is through the use of a screen of not greater than 20 mesh. As this step cuts off the filter cloth clogging sparing the cleaning efforts that usually amount to its 30%.

There is a 2-stage pressing process for the creation of a deeper extraction cake.

Regular Backwashing: Perform high-pressure backwashing (≥8 MPa) after every evacuation for the continuous flow process to be possible and avoid the risk of sludge pour out. The best advised frequency for washing is once per day for maintaining the best efficiency.

3. Manage Wear Parts Lifespan

Timely Repairs: When a filter cloth is in some way damaged, as soon as possible do not forget to fix it. If the damage has more than 5% per filter cloths then it is advisable to replace them, rather than risk contaminating the filtrate.

Seal Maintenance: Have a look at your seals at least once a week to see whether the integrity is still preserved. Change old components if they are causing leaks as this may waste money.

Hydraulic Oil and Seals: It is better to check the oil’s quality every 3 months, while the seal replacement should be done once a year.

4. Energy Management and Resource Recovery

Conserving energy is not only cost-effective, but it also helps the environment by minimizing the usage of resources.

Implement Energy-Saving Technologies

Heat Recovery: Utilization of the process heat (maintenance of 40-50°C) to warm the incoming sludge results in a decreased demand of additional energy for the rainy cold period when the agent for purification has to be warm.

Reuse Filter Liquids and Cakes

Filter Liquid Recycling: It is a green approach to process the filtrate and then employ it again as clean water for washing or other purposes, with as much as 20 tons of water being saved daily.

5. Employ Digital Management

Putting in place electronic oversight systems can bring about a greater level of efficiency and reduce costs.

Fit In Smart Monitoring Systems

Real-Time Data Monitoring: Monitor top metrics such as pressure, flow rate, moisture content, and chemical usage in order to see the condition of an item. The parameters falling below the acceptable thresholds can trigger alerts that will help in mitigating the operational issues.

Predictive Maintenance Models: Employ historical data to enable AI algorithms to make predictions on probable damages, like filter cloth damages, or bearing wear, thereby giving the owner the chance to be a step ahead in the planning of maintenance works.

Conclusion

Reducing the operating cost of a sludge filter press involves a multifaceted approach that includes careful equipment selection, process optimization, diligent maintenance, energy management, and digital monitoring.

At Jingjin Filter Press, we provide advanced solutions designed to meet your filtration needs while prioritizing cost-effectiveness and reliability. Contact us today to learn how our sludge filter presses help you.