How Does a Plate and Frame Type Filter Press Work in Industrial Filtration Systems?

Jul 29, 2025

In industries where solid-liquid separation is essential—such as wastewater treatment, mining, chemical processing, and food production—the Plate and Frame Type Filter Press remains one of the most reliable and cost-effective filtration systems. Despite the rise of automated alternatives, this classic design continues to deliver consistent results in small to mid-scale applications. At JingJin Filter, a global leader in industrial filter press technology, we offer robust and customizable plate and frame systems, along with advanced components like the Leaf Filter Plate, to meet the diverse filtration needs of modern industries.

What Is a Plate and Frame Type Filter Press?

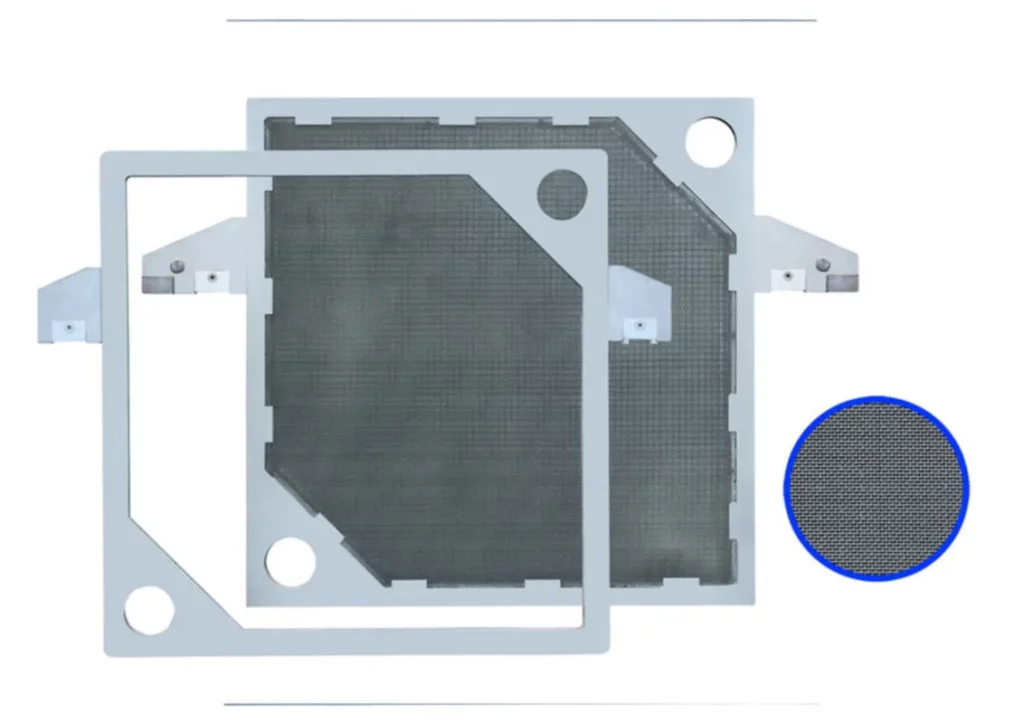

The Plate and Frame Type Filter Press is made up of alternating solid plates and hollow frames that are stacked vertically. A frame contains the slurry (a mixture of liquid and solids), while filter cloths that capture solids and allow filtrate to pass through are supported by the adjacent plates.

When slurry is introduced into the unit, the cloth will be clogged by solids as a filter cake is formed. After completing the operation of the press, it is opened, cakes are discharged, and the cycle is continued.

Although this model is relatively modest, it provides great control over:

- Thickness and washing quality of the cake

- Clarity and recovery efficiency of the filtrate

- System pressure and filtration speed

At JingJin Filter, we design our plate and frame filters for high durability, and they are widely used in batch processing, laboratory filtration, and low-volume but high-precision separation tasks.

Key Advantages in Industrial Filtration

The Plate and Frame Type Filter Press offers multiple benefits that make it relevant even today:

- High solid capture rate: Ideal for separating fine particles with low turbidity in the filtrate.

- Flexible design: Easily adjusted for different cake thicknesses and media types.

- Easy maintenance: Filter cloths can be replaced or cleaned without special tools.

- Cost-effective: Especially suited for operations not requiring full automation.

Its precision and adaptability make it highly compatible with downstream polishing systems, such as the Leaf Filter Plate, which can further refine filtrate quality where ultra-clarity is needed.

Integration with Leaf Filter Plate Technology

While the Plate and Frame Type Filter Press handles bulk separation, the Leaf Filter Plate is commonly used for fine filtration in critical industries like pharmaceuticals, edible oils, and specialty chemicals. At JingJin Filter, we help clients design hybrid systems where plate and frame presses perform the primary dewatering stage, and leaf plates provide post-filtration clarity and solid recovery.

This multi-stage approach ensures:

- Optimized throughput across different separation phases

- Reduced filter cloth wear and extended equipment life

- Consistent output quality for both filtrate and cake

By integrating these technologies into one cohesive system, JingJin enhances both filtration precision and operational flexibility.

JingJin’s Industrial Filter Press Expertise

As one of the most established industrial filter press manufacturers in the world, JingJin Filter offers complete filtration solutions tailored to client needs. Our Plate and Frame Type Filter Press models are available in a range of sizes and materials (including stainless steel and polypropylene) and can be fitted with automated hydraulic closure systems, cake washing modules, and customized filter media.

We serve a wide variety of industries, including:

- Municipal and industrial wastewater

- Mining tailings and mineral recovery

- Biotech, chemical, and food processing

- Pigments, ceramics, and pulp production

From initial design to technical support, JingJin ensures every system delivers reliable performance under tough industrial conditions.