How a Hydraulic Filter Press Improves Industrial Efficiency in South America

Oct 21, 2025

The Growing Demand for Hydraulic Filter Presses in South American Industries

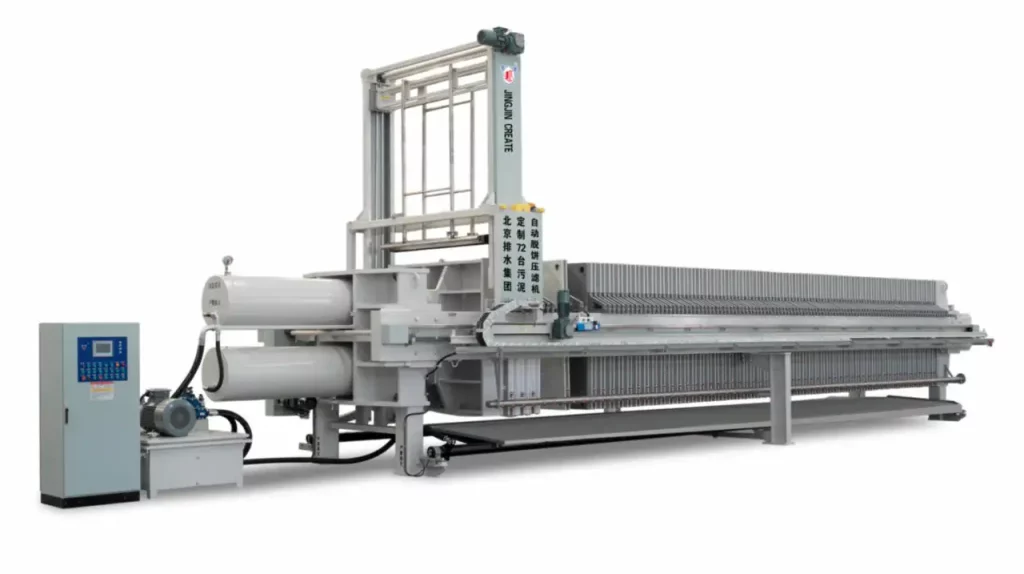

South America is witnessing rapid industrial growth in sectors such as mining, chemical processing, food production, and wastewater treatment. To handle large-scale solid-liquid separation, many companies are shifting toward automated solutions like the Filter Press. A hydraulic filter press offers consistent performance, high filtration precision, and reduced labor requirements—key advantages for industries facing increasing production and environmental demands.

The hydraulic system ensures stable pressure during filtration, improving dehydration efficiency while reducing cycle times. For mining and metallurgical operations, this means faster processing and lower moisture content in filter cakes, translating into cost savings and improved sustainability.

Why Hydraulic Filter Presses Are Ideal for Harsh Industrial Environments

In regions with tough working conditions—like the copper mines of Chile or wastewater plants in Brazil—durability and automation are crucial. A hydraulic filter press stands out because of its rugged structure and automatic pressure control. It can handle high-temperature, corrosive, and high-viscosity materials that traditional filtration systems struggle with.

The use of corrosion-resistant materials and intelligent PLC systems ensures reliable, long-term operation. For companies in South America aiming to improve their process reliability while minimizing downtime, this technology offers an excellent return on investment.

Key Benefits of Hydraulic Filter Press for Industrial Applications

- Automatic Operation: Fully hydraulic systems enable easy automation, reducing labor costs and human error.

- High Filtration Efficiency: Achieves consistent, dry filter cakes for improved material recovery.

- Adaptability: Suitable for mining tailings, food processing, pharmaceuticals, and chemical plants.

- Low Maintenance: Designed for long service life with minimal manual intervention.

- Energy Efficiency: Optimized hydraulic systems lower energy consumption and increase productivity.

By integrating modern filtration systems, South American companies can meet strict environmental standards while increasing profitability. Jingjin’s industrial filter press range is designed to meet these exact needs with customizable configurations.

How to Choose the Right Hydraulic Filter Press for Your Industry

When selecting a hydraulic filter press, key factors include plate size, filtration area, operating pressure, and automation level. For example, mining operations may require high-pressure units with heavy-duty plates, while food industries benefit from stainless steel models ensuring hygiene and easy cleaning.

Local support, spare part availability, and customization options are also vital. Jingjin provides tailored filter press systems engineered for different industries and environmental conditions, ensuring the best balance between performance and cost efficiency.

Jingjin – A Trusted Partner for Hydraulic Filter Press Solutions

With decades of expertise and global recognition, Jingjin is one of the world’s leading manufacturers of hydraulic and industrial filter press systems. Our solutions are certified under ISO and CE standards, ensuring compliance with international safety and quality requirements.

We serve clients across South America in sectors like mining, wastewater treatment, and food processing. From filter cloths to complete automatic filtration systems, Jingjin offers reliable, energy-efficient, and customized solutions that help industries reduce waste, improve production, and achieve environmental sustainability.

If your business seeks a dependable filtration solution for demanding industrial environments, Jingjin’s hydraulic filter press is the ideal choice to enhance productivity and long-term performance.