Industrial Water and Water Pollution: How Can Industries Effectively Minimize Contamination and Ensure Compliance?

Fév 13, 2026

Industrial water and water pollution are critical challenges for modern industries, including chemical processing, mining, food production, and manufacturing. Contaminated water can reduce operational efficiency, damage ecosystems, and lead to regulatory penalties. Companies need to implement comprehensive water management strategies that incorporate advanced treatment technologies, monitoring, and maintenance practices.

Understanding the sources of industrial water pollution and applying appropriate solutions ensures that industries can operate sustainably, comply with environmental regulations, and optimize resource usage.

Common Sources of Industrial Water Pollution

Industrial water pollution can originate from a variety of processes depending on the type of industry.

Chemical Effluents

Chemical plants, metal processing facilities, and mining operations often discharge acids, solvents, or reactive compounds into wastewater. These chemicals can disrupt aquatic ecosystems and create compliance issues if not properly treated. Employing neutralization and chemical precipitation methods reduces toxicity and prepares wastewater for further treatment.

Suspended Solids

Food processing, mineral extraction, and construction industries frequently generate high concentrations of suspended solids. These particles increase turbidity and strain downstream treatment systems. Utilizing solid liquid separation equipment allows industries to efficiently remove solids, improving water clarity and protecting treatment infrastructure.

Heavy Metals

Certain industrial activities release heavy metals such as lead, mercury, and cadmium, which pose significant environmental and health risks. Advanced treatment systems, including precipitation and filtration, are required to remove these metals from wastewater streams before discharge.

Thermal and Organic Contaminants

Water discharged at elevated temperatures or containing high organic content can harm aquatic life. Biological pollutants, including bacteria and nutrients that promote algal blooms, further complicate treatment. Temperature control, retention systems, and biological treatment processes are essential for minimizing these impacts.

Industrial Water Treatment Technologies

Mechanical Filtration and Dewatering

Mechanical filtration is a fundamental step in industrial wastewater management. A high-performance industrial filter press can process large volumes of slurry, producing clear filtrate while minimizing sludge volume.

Advantages of Industrial Filter Presses

- Capture high concentrations of solids efficiently

- Enable recovery of valuable byproducts

- Support continuous industrial operation with minimal downtime

Maintenance Best Practices

- Regular inspection of filter plates and cloths

- Monitor feed slurry concentration and pressure

- Implement scheduled preventive maintenance to avoid unexpected failures

Chemical Treatment

Chemical precipitation, coagulation, and flocculation are effective for removing dissolved metals and fine particulates. Precise dosing, effective mixing, and monitoring are critical to achieving optimal removal and consistent water quality.

Biological Treatment

Activated sludge systems and biofilters degrade organic contaminants. These methods are widely used in food, beverage, and pharmaceutical industries to reduce biological oxygen demand (BOD) and ensure effluent compliance.

Integrated Treatment Systems

Many facilities combine mechanical, chemical, and biological methods to treat complex effluents. An integrated approach enables water reuse, reduces environmental impact, and ensures compliance with stringent regulations.

For tailored solutions for your facility, contact our team to discuss customized industrial water treatment systems.

Performance Metrics for Industrial Water Management

Monitoring key parameters ensures water treatment systems operate efficiently and meet regulatory requirements.

Table 1: Essential Industrial Water Treatment Metrics

| Parameter | Typical Range | Measurement Method | Notes |

|---|---|---|---|

| Suspended Solids | <50 mg/L | Gravimetric or turbidity test | Depends on feedwater quality |

| Chemical Oxygen Demand (COD) | <100 mg/L | Standard chemical test | Reflects organic load |

| pH | 6.5–9.0 | pH meter | Ensures regulatory compliance |

| Heavy Metals | Within regulatory limits | Atomic absorption spectroscopy | Varies by industry |

Case Studies of Effective Water Pollution Control

Mining Operations

Tailings and slurry from mining operations often contain heavy metals and high solid content. Implementing a Jingjin filter press reduced suspended solids by over 80%, improved water reuse, and lowered disposal costs.

Chemical Manufacturing

Chemical plants combining precipitation and filter press dewatering successfully minimized heavy metal discharge, meeting stringent environmental regulations.

Food Processing Facilities

High BOD organic wastewater was dewatered using filter presses, reducing biological contamination and improving treatment efficiency.

Power Generation

Thermal discharges from power plants were mitigated using cooling systems combined with filtration, reducing water temperature before release and protecting aquatic ecosystems.

Challenges and Solutions

Excessive Solids

- Cause: Inefficient separation or improper equipment selection

- Solution: Use high-efficiency industrial water and wastewater treatment systems with proper monitoring and maintenance

Chemical Overload

- Cause: Improper dosing or incomplete reactions

- Solution: Employ automated chemical dosing and real-time monitoring

Thermal Pollution

- Cause: High-temperature effluent discharge

- Solution: Install retention tanks or heat exchangers to reduce temperature before environmental release

Sludge Management

- Cause: Large volumes of sludge from solid-liquid separation

- Solution: Dewater sludge with filter presses to reduce disposal costs and allow resource recovery

FAQ

What is industrial water pollution?

Industrial water pollution is contamination caused by chemicals, solids, or thermal discharge from industrial processes.

How does a filter press assist in treatment?

Filter presses remove solids efficiently, reduce sludge volume, and produce clear filtrate suitable for reuse or discharge.

How often should equipment be maintained?

Daily inspections, weekly cleaning, and quarterly performance evaluations are recommended.

Can treated water be reused?

Yes, treated water can reduce freshwater consumption and operational costs.

Which regulations govern industrial wastewater?

Regulations vary globally, including the U.S. EPA standards and the EU Water Framework Directive.

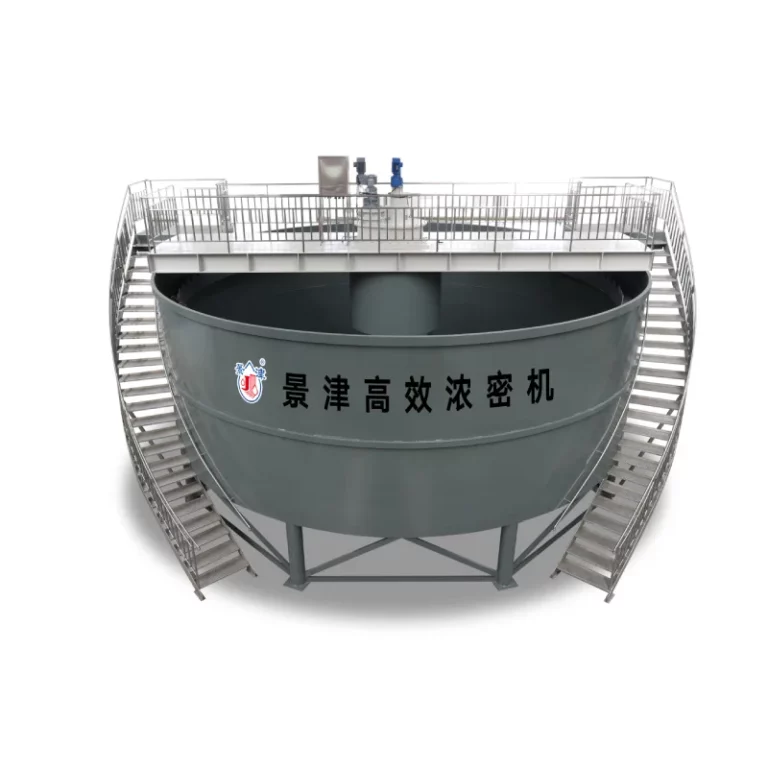

About Jingjin

Jingjin specializes in providing advanced industrial filter press solutions for industries worldwide. Our systems are designed for efficiency, reliability, and compliance across mining, chemical, food, and municipal sectors. By leveraging our expertise, industries can achieve sustainable water management while optimizing operational performance.

References

- Industrial water – Wikipedia

https://en.wikipedia.org/wiki/Industrial_water - Water pollution – Wikipedia

https://en.wikipedia.org/wiki/Water_pollution - Industrial wastewater treatment fundamentals – Water Environment Federation

https://www.wef.org/resources/ - Solid-liquid separation – ScienceDirect

https://www.sciencedirect.com/topics/engineering/solid-liquid-separation