Product Categories

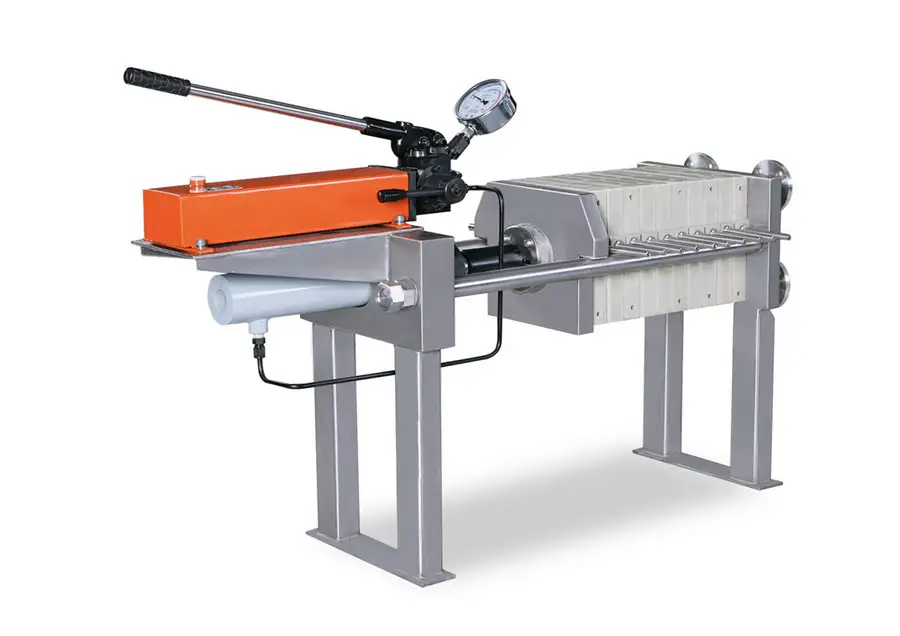

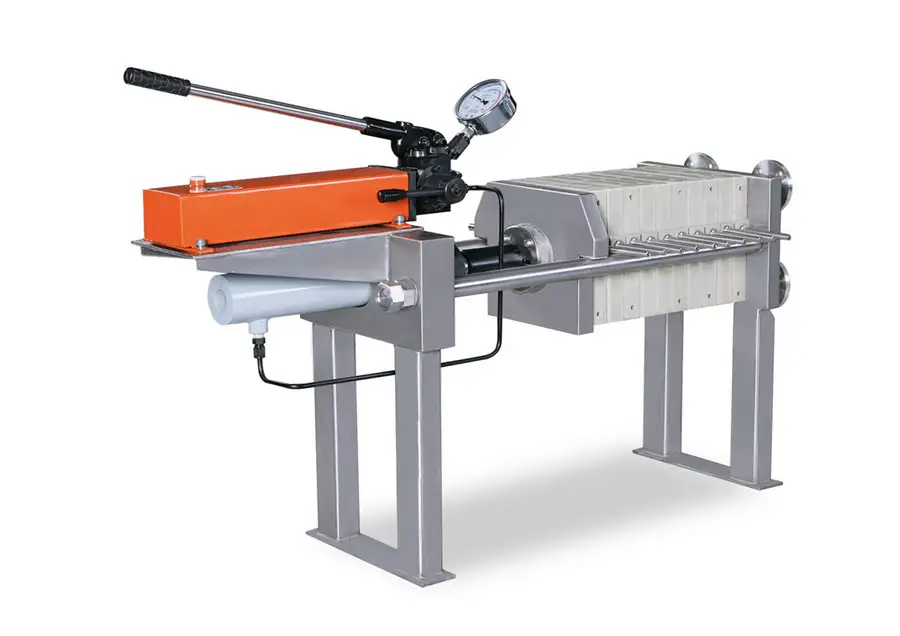

Model 250 Manual Filter Press

| Place of Origin: | Shandong, China |

|---|---|

| Brand Name: | JINGJIN |

| Warranty: | 12 months |

For customized product solutions, please reach out to us!

Your satisfaction is our commitment!

Jingjin will always be your trusted partner!

Quick Details of Model 250 Manual Filter Press

Model 250 Manual Filter Press details are as below:

| Condition: | New |

|---|---|

| Automatic Grade: | Automatic |

| Production Capacity: | High efficiency |

| Place of Origin: | Shandong, China |

| Brand Name: | Jingjin |

| Model Number: | 2000×2000 |

| Voltage: | 3ph/380V50HZ.3ph/415V/50HZ, 3ph/440V/60HZ. or other |

| Power: | Total 9.55kw |

| Weight: | 18800kg |

| Dimension(L*W*H): | 14120*2800*2300 Mm3 |

| Warranty: | 1 Year |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Certification: | CE,ISO9001:2008 |

| Plate shifting method:: | Automatic shifting one by one |

| Feeding method:: | Single and center feeding |

| Power type: | Automatic hydraulic press and open |

| Cloth washing: | Automatic cloth washing one by one |

| Drip tray: | Stainless steel material.Auto open and close |

| Color: | Blue, Yellow, Green, White, Grey, Brown,etc |

Jingjin Environmental Protection Inc. started in 1998. It’s a full-service company in the environmental protection industry. The company makes filtration equipment, provides complete filtration technology solutions, and manages environmental protection projects from start to finish. As a vice president of the China Environmental Protection Industry Association, Jingjin led the effort to write national standards for filter presses and filter plates.

For 12 years in a row, Jingjin has had the biggest production and sales of filter presses in the world. Its products are sold in 123 countries and regions. The Chinese government named the Jingjin trademark a ‘Famous Chinese Trademark,’ and it has international protection through Madrid International Trademark Registration. Water Jiang, the company’s chairman, won the titles of National Labor Model and National Model Worker.

Technical Advantage of Model 250 Manual Filter Press

The Jingjin frame uses Q345B material. Its tensile strength is 1.4 times that of Q235, which makes the Jingjin filter press safer and more stable to operate. We use carbon dioxide shielded welding to make the oil cylinder seat, pressing plate, and thrust plate, so they’re very sturdy.

The main beam of the Jingjin filter press has a welded box design. We make it with advanced submerged arc automatic welding technology. To make spare parts last longer, we use high – speed centrifugal ball blast to remove rust and scale before painting them. Then, we apply a MIO epoxy build primer and an acrylic polyurethane coating. This way, the coating sticks well. This process cuts down on using hundreds of tons of putty every year, saving costs and helping the environment. It also makes the paint stick better and improves the filter press’s ability to resist corrosion.

Model 250 Manual Filter Press Features

- Capacity: The “250” in the model name usually shows the filter press’s capacity. This could mean the size of the plates, how much slurry it can process in one cycle, or the total area for filtering. Without more info, we can guess it’s a medium-sized model, good for filtering jobs that aren’t too big or too small.

- Manual Operation: This is a manual filter press, so you have to open and close it by hand. After each cycle, you also need to remove the filtered cake manually.

- Filtration Area: The filtering area is probably around 250 square meters or something similar, depending on how the press is designed and the size of the plates. The filtration area matters a lot because it determines how much the press can process and how efficient it is.

- Plate Size: Each filter plate is likely about 250 mm x 250 mm or close to that size. But the real dimensions can change based on what the manufacturer specifies.

- Maximum Pressure: Manual filter presses generally work at lower pressures than automatic or hydraulic ones. The highest pressure it can handle depends on the design, but it’s often around 1 to 2 bar (or 14.5 to 29 psi).

- Materials of Construction: The materials for the plates and frame depend on what you’re using the filter press for and the type of slurry you’re filtering. Common materials are polypropylene, stainless steel, and other alloys that resist corrosion.

- Ease of Use: Sure, manual operation takes some physical work. But because the design is simple, these filter presses are fairly easy to use and keep in good shape.

If you are interested in our products, please contact us !