Industrial Filters Manufacturers: How to Choose the Right Partner for Efficient and Sustainable Filtration

Dic 18, 2025

In today’s industrial landscape, filtration is no longer a secondary process hidden behind production lines. It has become a critical factor that directly affects operational efficiency, product quality, regulatory compliance, and long-term cost control. For procurement managers, plant engineers, and decision-makers, selecting the right industrial filters manufacturers is a strategic decision that influences the entire lifecycle of an industrial project.

Across industries such as wastewater treatment, mining, chemicals, metallurgy, food processing, and pharmaceuticals, filtration systems act as the backbone of stable operations. A well-designed filtration system enhances throughput, minimizes downtime, and reduces waste. Conversely, poor filtration choices often lead to frequent maintenance, unexpected shutdowns, and rising operational costs.

This article explores what differentiates leading industrial filters manufacturers, the core challenges faced by B2B buyers, and how to identify a reliable filtration partner capable of supporting both current production needs and future growth.

What Sets Leading Industrial Filters Manufacturers Apart

Not all industrial filters manufacturers offer the same level of value. While many suppliers can deliver filtration equipment, only a few demonstrate the technical depth, manufacturing strength, and long-term vision required for demanding industrial applications.

Engineering capability is the first major differentiator. Leading manufacturers invest continuously in research and development to improve filtration efficiency, mechanical strength, and system automation. As industrial processes become more complex and environmental regulations more stringent, filtration technology must evolve accordingly. Manufacturers with strong engineering teams are better positioned to adapt designs to new challenges rather than relying on outdated, standardized solutions.

Manufacturing capacity is equally important. Advanced production facilities, precision machining, and strict quality control systems ensure consistency across large-scale orders. For B2B buyers managing multiple plants or large infrastructure projects, consistency in product quality is not optional, it is essential.

Industry experience also plays a critical role. Manufacturers with decades of hands-on project experience understand the realities of industrial environments, including abrasive slurries, corrosive chemicals, high temperatures, and fluctuating operating conditions. This practical knowledge allows them to propose filtration systems that perform reliably over long service cycles.

Finally, global service capability distinguishes top-tier manufacturers from regional suppliers. Industrial operations often span multiple countries, and manufacturers who can provide international technical support, spare parts supply, and after-sales service reduce risk and simplify procurement decisions.

Key Industrial Filtration Challenges Faced by B2B Buyers

Modern industrial filtration operates under growing pressure from cost control, environmental compliance, and performance optimization. B2B buyers must balance these often competing priorities when selecting filtration systems.

One major challenge is handling increasingly complex materials. Higher solid concentrations, finer particle sizes, and chemically aggressive media place greater demands on filtration equipment. Systems must deliver precise separation while maintaining mechanical durability and stable performance.

Operational continuity is another critical concern. Filtration system failures can halt entire production lines, leading to significant financial losses. As a result, buyers prioritize filtration solutions that offer automated operation, stable pressure control, and simplified maintenance procedures to reduce downtime.

Environmental regulations also continue to tighten worldwide. Industrial facilities are under increasing scrutiny regarding wastewater discharge, solid waste reduction, and resource reuse. This has driven strong demand for advanced industrial filtration solutions that help companies meet sustainability goals while maintaining economic viability.

In addition, total cost of ownership has become a key evaluation metric. Beyond initial purchase price, buyers now focus on energy consumption, filter media lifespan, labor requirements, and long-term maintenance costs. Manufacturers that address lifecycle efficiency gain a clear competitive advantage.

The Role of Advanced Filtration Equipment in Industrial Efficiency

Filtration equipment has evolved from a passive component into an active driver of industrial efficiency. Modern systems are designed to integrate seamlessly with production processes, delivering consistent performance while reducing manual intervention.

Automation plays a significant role in this transformation. Intelligent control systems monitor filtration cycles, pressure differentials, and flow rates in real time, ensuring optimal operation under varying conditions. This not only improves separation efficiency but also enhances workplace safety and operational predictability.

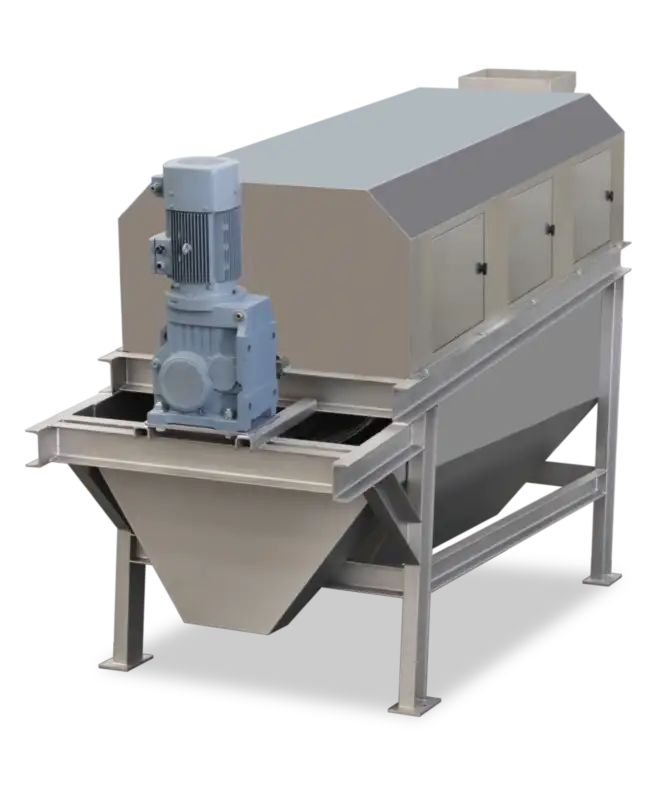

Equipment such as filter press machines has become a cornerstone solution for industries dealing with high-solid-content slurries. These systems are engineered to achieve high dewatering efficiency, producing drier filter cakes and clearer filtrate. The benefits extend beyond improved separation, including reduced waste volume, lower transportation costs, and simplified downstream handling.

Advanced filtration equipment also supports resource recovery and reuse. In many industries, recovered solids can be reused as raw materials, while treated water can be recycled back into production processes. This circular approach aligns with sustainability objectives and reduces overall operating costs.

Why Customization Matters in Industrial Filtration Projects

One of the most common mistakes in industrial filtration procurement is assuming that standard equipment will perform equally well across different applications. In reality, each industrial process presents unique challenges that require tailored solutions.

Customization begins with a thorough understanding of process conditions. Factors such as slurry composition, particle size distribution, operating temperature, chemical compatibility, and filtration accuracy all influence system design. Ignoring these variables often results in suboptimal performance and shortened equipment lifespan.

Leading industrial filters manufacturers treat customization as a core capability rather than an optional service. This may involve selecting specialized filter media, optimizing plate structures, adjusting operating pressures, or integrating automation features to suit specific applications.

Customized filtration systems offer measurable benefits, including improved efficiency, reduced maintenance frequency, and longer service intervals. For industries such as mining, metallurgy, chemicals, and municipal wastewater treatment, these advantages translate directly into operational stability and cost savings.

How to Evaluate and Select the Right Industrial Filters Manufacturer

Selecting the right manufacturer requires a structured and strategic approach. B2B buyers should look beyond product specifications and consider the manufacturer’s overall capabilities and long-term reliability.

Technical strength should be evaluated first. Certifications, testing facilities, and engineering credentials provide insight into a manufacturer’s commitment to quality and innovation. Strong technical foundations indicate an ability to support complex projects and evolving requirements.

Project experience is another key indicator. Manufacturers with a proven track record in similar industries are more likely to deliver solutions that perform as expected. Case studies and references offer valuable evidence of real-world performance.

Supply chain stability also matters. Reliable sourcing of raw materials, in-house manufacturing, and efficient logistics systems ensure consistent product quality and timely delivery, especially for large or repeat orders.

After-sales service should never be underestimated. Installation support, operator training, maintenance guidance, and spare parts availability protect the buyer’s investment throughout the equipment lifecycle.

Finally, consider the manufacturer’s strategic direction. Companies focused on sustainability, digitalization, and continuous improvement are better positioned to support long-term industrial partnerships.

Jingjin: A Trusted Name Among Global Industrial Filters Manufacturers

Jingjin is recognized globally as one of the leading industrial filters manufacturers, offering comprehensive filtration solutions for a wide range of industries. With decades of experience, Jingjin combines advanced engineering, large-scale manufacturing capability, and strict quality control to deliver reliable and efficient filtration systems.

The company’s product portfolio covers diverse industrial applications, including wastewater treatment, mining, chemical processing, and metallurgy. Jingjin’s filtration equipment is designed to operate reliably under demanding conditions while maintaining high separation efficiency and long service life.

By focusing on innovation, customization, and customer support, Jingjin helps industrial clients reduce operating costs, improve environmental compliance, and achieve sustainable production goals. For businesses seeking a long-term filtration partner rather than a short-term supplier, Jingjin represents stability, expertise, and proven performance.