How Innovative Filter Plate Design Enhances Industrial Filtration Efficiency

Oct 13, 2025

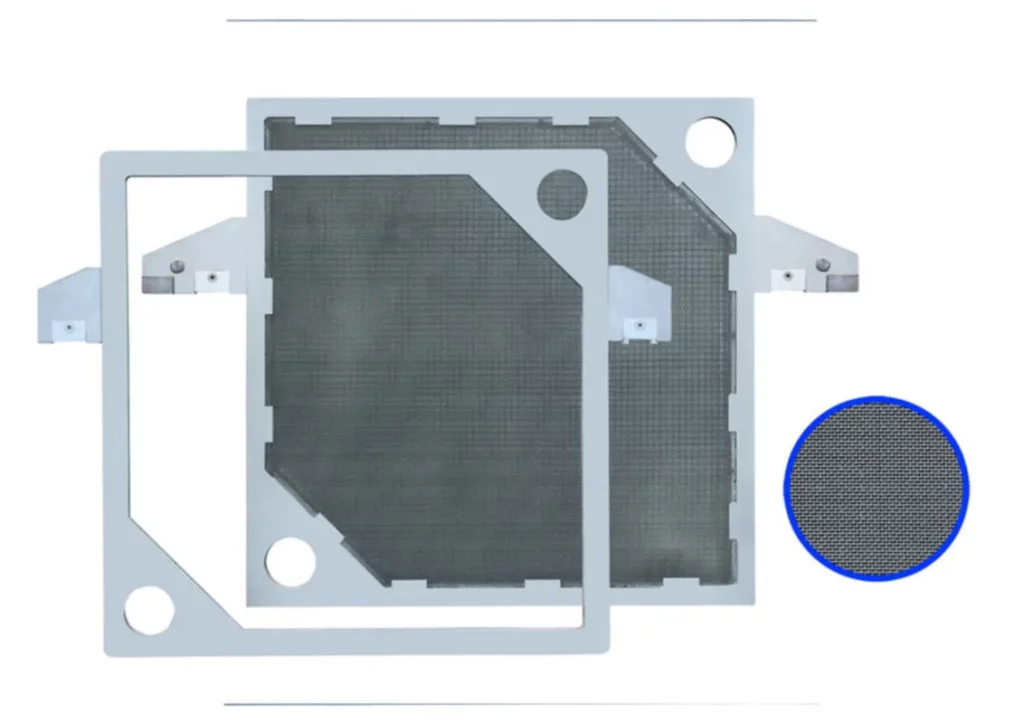

The Importance of Filter Plate Design in Industrial Filtration

For industries across Central and South America—such as mining, food processing, and wastewater treatment—filtration performance directly affects productivity and cost efficiency. At the core of every industrial filter press, the filter plate design determines how effectively solids are separated from liquids. A well-engineered filter plate ensures uniform pressure distribution, faster cycle times, and minimal moisture in the filter cake, leading to cleaner output and reduced waste handling.

Key Factors in Advanced Filter Plate Design

Modern filter plate design goes beyond simple structure; it combines engineering precision with material innovation. The choice of plate material—polypropylene, steel, or membrane—affects filtration speed and resistance to corrosion. Surface pattern, drainage channels, and sealing edges all play essential roles in optimizing filtration performance. For example, membrane filter plates can inflate during operation, squeezing out additional moisture and improving dryness levels by up to 30%. This efficiency is especially valuable for industries in humid climates common throughout Latin America.

How Filter Plate Design Impacts Operational Costs

A high-quality filter plate contributes to long-term cost savings by reducing maintenance downtime and energy consumption. Poorly designed plates can cause uneven pressure, leading to leaks, plate damage, and frequent replacements. In contrast, a robust industrial filter press with well-optimized plates maintains stable operation even under variable process conditions. This consistency minimizes production interruptions and extends the lifespan of other filtration components, such as the Filter Cloth, which must work in perfect coordination with the plates.

Customization for Industry-Specific Applications

Different industries require unique plate configurations. In the mining sector, high-pressure filtration is necessary to handle abrasive materials, while in the food and beverage industry, hygiene and easy cleaning are top priorities. Custom filter plate design allows each application to achieve the right balance of filtration rate, cake dryness, and durability. For clients in Central and South America, customization also ensures compatibility with local process conditions and environmental regulations, helping companies achieve both performance and sustainability goals.

Jingjin — Your Trusted Filtration Technology Partner

As a global leader in filtration solutions, Jingjin has dedicated over three decades to innovating filter plate and press technology. Our engineering team continuously refines plate structure and materials to meet the highest industrial standards. Whether you require high-capacity presses, corrosion-resistant designs, or specialized plates for challenging processes, Jingjin delivers precision-engineered solutions tailored to your needs. Explore our full range of filtration systems at industrial filter press to see how Jingjin can help your operation achieve higher efficiency, cleaner output, and reduced costs.