Matec Filter Press: Tailored Dewatering Solutions for Mining, Recycling, and Industrial Sludge

Jun 17, 2025

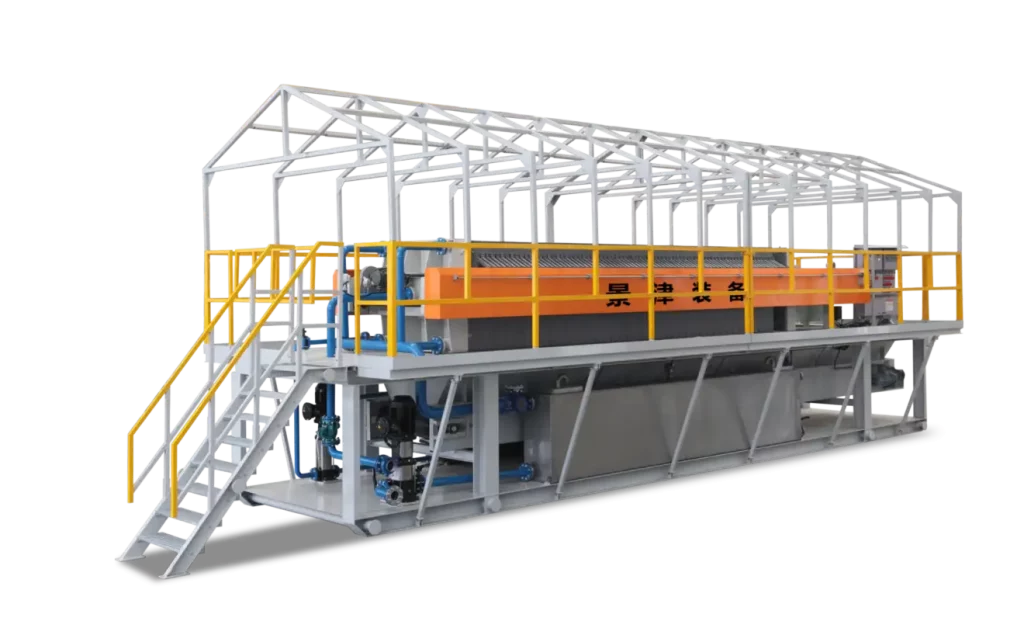

JingJin Filter Delivers Cost-Effective Alternatives with Advanced Filtration Engineering

Just like mining, construction recycling, and wastewater treatment industries are increasingly under pressure to innovate for dewatering and environmental regulations, and as a result, filter press technology has now become the veritable pillar of solid-liquid separation. From among the global examples, the Matec filter press is known for its extremely high-pressure performance. On the other hand, JingJin Filter is a new name in the filtration industry but also a high-quality provider—the company has come up with a stand-out product that successfully competes with leading brands both in terms of performance and reliability, while it is still greatly cost-effective and flexible.

When determining if it is the belt filter press price for a large scale that you are interested in, the alternative to the plate and frame press filter, JingJin Filter is your go-to source for a solution that is customizable and embodies the characteristics of precision, durability, and smart automation.

What Is a Matec Filter Press Equivalent?

The Matec filter press is known for its full-automatic hydraulic presses, typically used in high-demand fields like mining tailings, marble and granite sludge, and industrial wastewater. These systems operate under high pressure (up to 30 bar) to deliver fast cycle times and dry filter cakes with extremely low moisture content.

JingJin’s equivalent systems offer:

- Automated high-pressure operation

- Membrane squeezing and cake drying

- Smart PLC control with remote diagnostics

- Custom plate materials (PP, iron, or rubber-coated)

These features make JingJin’s presses a cost-effective and high-performing alternative to the Matec line, especially when paired with advanced filter cloths and fast after-sales service.

Why Consider JingJin Over Belt Filter Presses?

When comparing dewatering solutions, the belt filter press price may seem attractive for high-volume, continuous-flow systems. However, belt presses typically produce wetter cakes and require more maintenance due to their moving belts and rollers.

In contrast, JingJin’s plate and frame press filter and automatic membrane filter presses provide:

- Higher solids capture rate

- Lower final moisture content

- Greater pressure range and structural durability

- Reduced polymer and energy consumption

For industries that demand dry cakes for cost-effective transport or safe disposal, JingJin’s filter presses offer significantly better long-term value—especially in mining, quarrying, and industrial sludge treatment.

Application Highlights: Mining, Recycling, and Sludge

JingJin’s Matec filter press corresponding systems are a common solution to the following:

- Mining tailings management: Effectively removes the water from mineral fines thus decreasing the tailing pond volume, and subsequently makes water recycling feasible.

- Stone and ceramic cutting: Graces slurry that is much finer made during the process of marble, granite, and tile polishing, besides that, it defines the condition of the floor and water recovery and reuse can be facilitated.

- Industrial and municipal sludge: Its function is to extract the organic or chemical sludge from the wastewater, and then, through the process of irradiation, the obtained cakes are less smelly and take less space.

Every system can be configured according to the customer’s needs, e.g., it can be semi-automatic or fully automatic, equipped with cloth washing systems, cake blowout, etc.

JingJin’s Competitive Advantages

As a trusted international brand in filtration, JingJin Filter provides:

- Wide model range: From lab-scale units to industrial systems with >1000 m² filter area

- Rapid engineering and delivery: Global supply capacity for urgent projects

- Competitive pricing: Lower than Matec or other EU/US-based suppliers

- Full technical support: Remote diagnostics, installation guidance, and local spare parts

Combined with decades of industry experience and ISO-certified manufacturing, JingJin ensures every press delivers long-term performance with minimal downtime.

Tailored Dewatering Starts Here

Filter press selection is not only down to pressure. It’s all about the exact match to your material, moisture goals, and budget. In the case of Matec, belt, or classic plate and frame press filter, the key word is the technology that they are using, which means that they should just be appropriate options for the queries. For your part, – you have the benefit of JingJin Filter who develops proven and smart filtration solutions for the most challenging industrial applications.

Showcased from mining that is heavy-duty to really sophisticated ceramic slurries and very polluted sludges, the JingJin Filter is taking you closer to the dream of clear separation, disposal costs cut, and an increment in environmental friendliness.