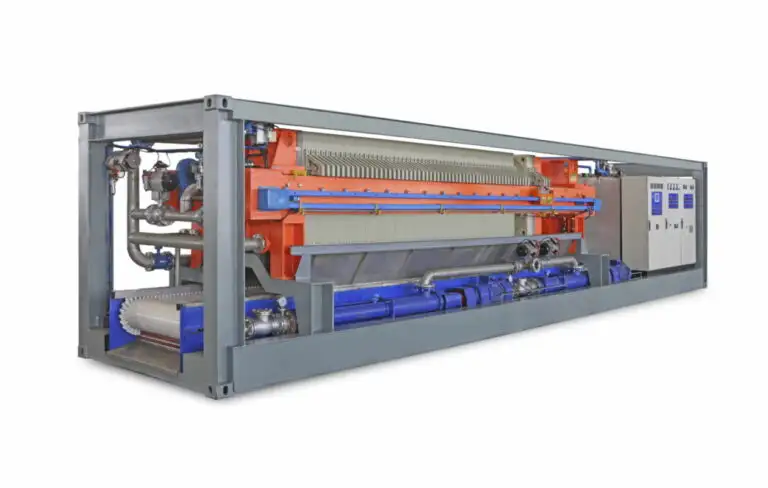

Automatic Filter Press Systems: The Key to Smarter, Cleaner, and Faster Industrial Filtration

Okt 21, 2025

The Growing Need for Automated Filtration in South America

Across South America, industries such as mining, wastewater treatment, chemicals, and food processing are under pressure to improve production efficiency while meeting environmental regulations. Traditional manual filtration methods can no longer keep up with increasing demands. This is where Automatic Filter Press Systems come in—offering high efficiency, reduced labor, and consistent performance.

With full automation for plate shifting, cake discharge, and cloth washing, these systems streamline operations and eliminate human error. For modern factories aiming to reduce costs and improve environmental performance, investing in a Filter Press with automatic control is a smart long-term decision.

Advantages of Using Automatic Filter Press Systems

Automatic systems deliver measurable improvements in industrial operations.

- Higher Productivity: Shorter cycle times and continuous operation increase throughput.

- Labor Reduction: Fully automated systems require minimal manual supervision.

- Improved Safety: Hydraulic and pneumatic controls ensure stable pressure and safe operation.

- Uniform Quality: Automated pressure management guarantees consistent cake dryness and purity.

- Energy Efficiency: Advanced hydraulic systems reduce energy consumption.

These benefits make the technology especially valuable in countries like Chile, Brazil, and Peru, where industrial growth demands reliable and eco-friendly equipment.

Smart Control and Real-Time Monitoring for Industrial Filtration

The next generation of Automatic Filter Press Systems integrates smart technologies like PLC and HMI controls, allowing operators to monitor, adjust, and optimize parameters in real time. This results in improved filtration accuracy, reduced downtime, and better overall efficiency.

For industries dealing with varying material characteristics—such as mining or chemical processing—intelligent automation ensures stability even under fluctuating conditions. Jingjin’s systems offer customizable automation levels that fit diverse industrial needs. If your business seeks a robust and efficient industrial filter press solution, automation is the key to achieving operational excellence.

Wide Applications Across South American Industries

Automatic filter press systems are transforming industries across South America:

- Mining & Metallurgy: Dewatering mineral tailings and recovering valuable resources.

- Wastewater Treatment: Removing sludge efficiently and meeting environmental standards.

- Food & Beverage: Producing cleaner liquids with efficient solid separation.

- Chemicals & Pharmaceuticals: Achieving precise filtration for high-purity production.

By reducing human involvement and improving control, these systems help companies save time, cut costs, and meet sustainability targets.

Jingjin – Your Trusted Partner for Advanced Filtration Solutions

With decades of expertise, Jingjin is a world-leading manufacturer of Automatic Filter Press Systems and other advanced filtration equipment. Our products meet international certifications such as ISO and CE, ensuring the highest standards of safety and reliability.

Jingjin provides customized solutions to customers throughout South America, offering full support from system design to after-sales service. Whether you need a semi-automatic setup or a fully automated filtration line, we deliver high-performance systems designed for long-term durability and efficiency.

Discover how Jingjin’s industrial filter press technology can help your business achieve cleaner production, lower operational costs, and a smarter future in industrial filtration.