What is a thickener?

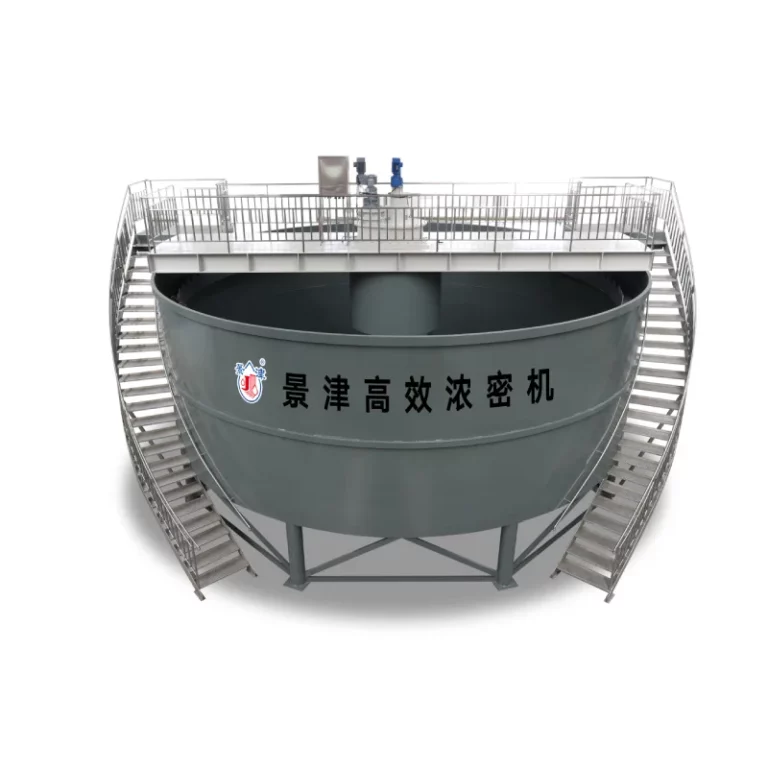

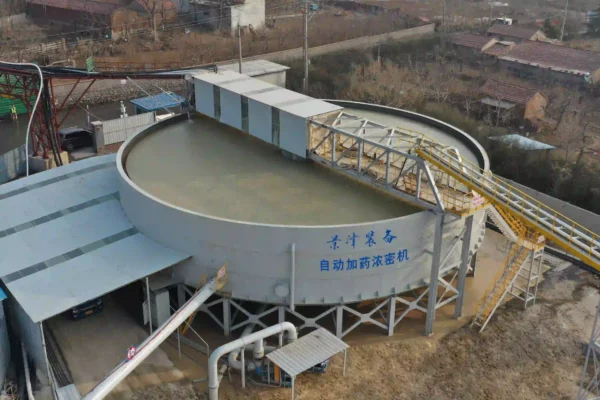

Jingjin thickener separates solids from liquids. People mainly use it in mining, metallurgy, and chemical industries. Thickeners play a vital role in industrial production. They boost efficiency, save resources, and reduce harm to the environment. Their main job is to separate solid particles floating in a liquid by using gravity to make them settle. This process concentrates the sludge and separates the clear liquid. There are many kinds of thickeners. The most common ones are conventional thickeners, high-efficiency thickeners, and deep cone thickeners. Each type works best in different conditions and meets various processing needs. For example, high-efficiency thickeners can handle a large amount of material, make solids settle fast, and take up less space. So, they’re great for tasks that need high processing speed and quick concentration.

![Thickener]()

Why Choose Thickener

- Boost Product Viscosity or Consistency:Thickeners are new functional polymer materials. Using just a small amount can greatly increase a product’s viscosity or consistency.

- Enhance Product Stability and Performance:Thickeners do more than increase viscosity. They also make products more stable, improve how they feel, stop components from separating, and keep emulsions stable.

- Widely Used:People use thickeners in many industries, like pharmaceuticals, printing and dyeing, cosmetics, food additives, oil production, papermaking, and leather processing.

- Many Types Available:There’s a wide variety of thickeners. You can pick different types based on your needs, such as low molecular thickeners, polymer thickeners, inorganic thickeners, cellulose, polyacrylates, and associative polyurethane thickeners.

- Increase Production Efficiency and Cut Costs:In the mineral processing industry, thickeners speed up the separation of solids and liquids. This boosts production efficiency and lowers costs.

- Optimize Operation and Maintenance:In the mining industry, using and maintaining thickeners properly is key. It ensures they work efficiently, maximizes mineral recovery, and makes the equipment last longer.

Classification of Thickeners:

- Deep Cone Paste Thickeners:These work well for concentrating different types of concentrates. They can raise the material concentration to over 65%.

- Ordinary High-Efficiency Thickeners:We designed these for concentrating various tailings. They can boost the material concentration to more than 40%.

- Intelligent Flocculant Dosing Detection System:This system adjusts the flocculant dosage automatically according to the incoming material concentration. It helps save 30% of the flocculant.

![Thickener]()

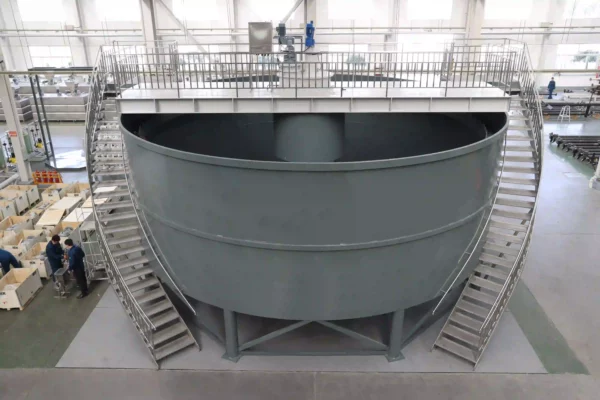

Features of Thickeners:

- Drive Systems and Pool Sizes:You can choose a single, double, or four-wheel drive system. The pool diameters vary from 8 to 50 meters. Use a single drive for pools under 20 meters in diameter, a double drive for pools 20 – 35 meters in diameter, and a four-wheel drive for pools 35 – 50 meters in diameter.

- Automatic Sludge Discharge:It discharges sludge automatically based on torque, which keeps the discharge stable. In the tailings industry, for instance, you can set it to start discharging when the underflow concentration hits 35%.

- Flocculant Dosing Integration:It can work with an automatic flocculant dosing detection system. This helps cut flocculant use by 40%.

- Special Flocculation Box:It has a special flocculation box. This box makes sure the flocculant fully reacts with the materials before they enter the center cylinder. Other manufacturers usually add the flocculant straight into the center cylinder. This causes incomplete reactions and wastes the flocculant.